Product Description

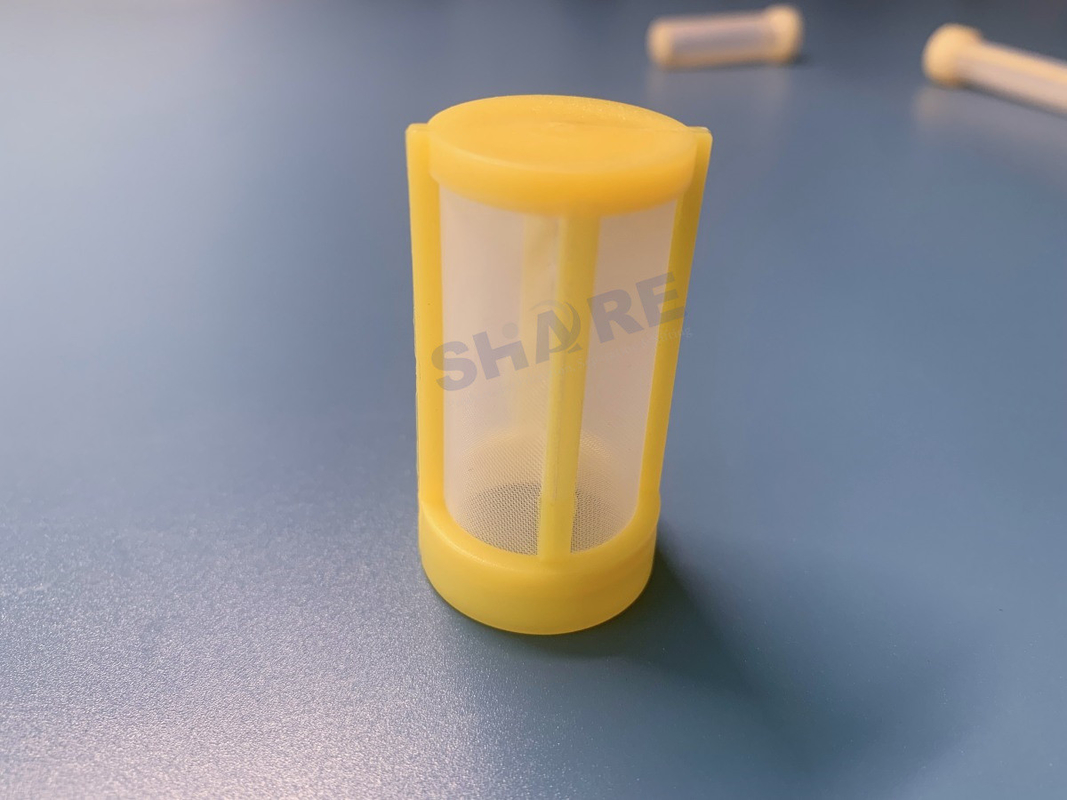

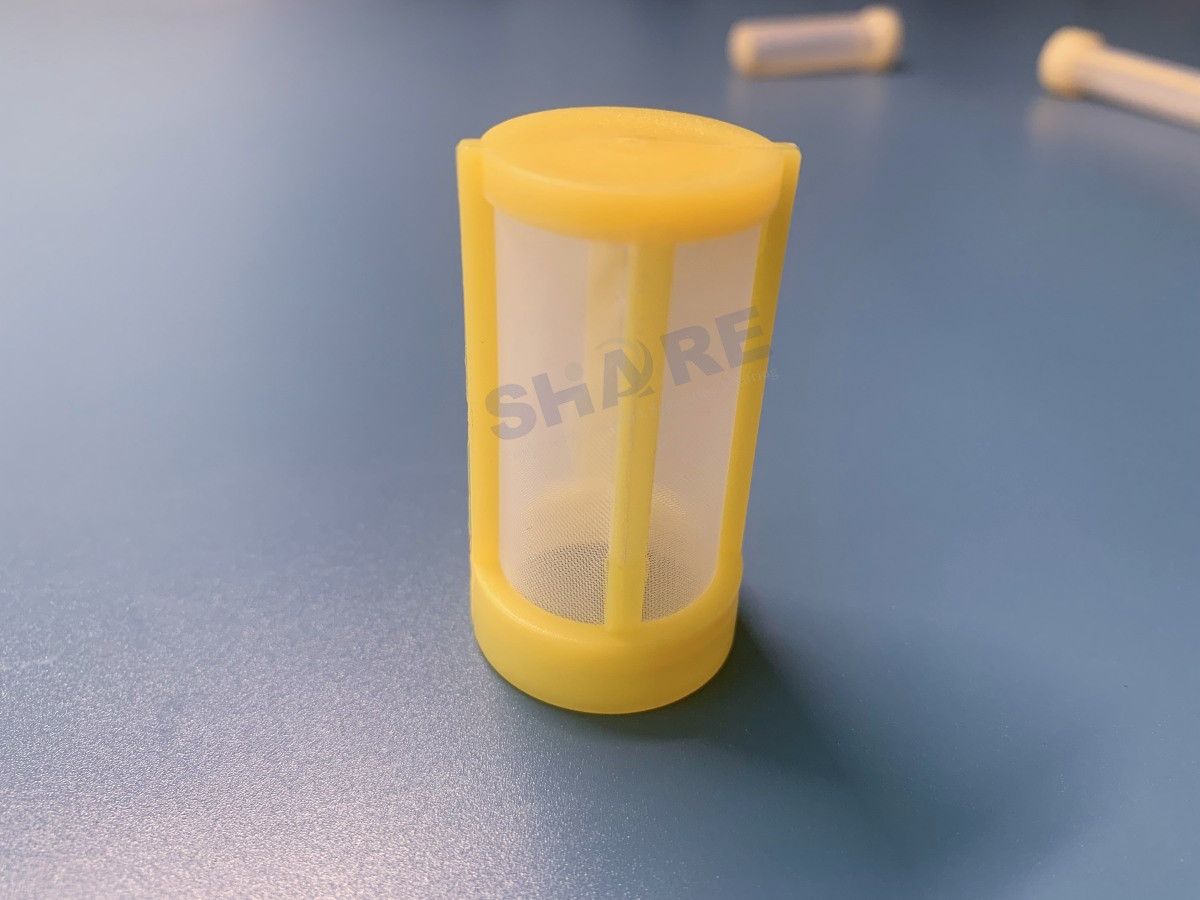

Homemade Cheese Separator Filter Custom Plastic Moulded Soy Milk Strainer

Share Filters' Injection moulded cheese separator filter combines the nylon or polyester filter mesh with thermoplastic, allowing for a more robust part giving more reliability and longevity in its use. Injection moulding can take many forms and Share Filters is fully capable to help develop and produce the injection moulded filter products according your drawing that will best suit your needs, as well as, offering any additional advice or service along the way.

Share Filters Homemade Cheese Separator Filter Material Options

|

Support rim material |

PA, PET, PP, PC, PE, etc. |

| Filter media |

Nylon mesh, polyester mesh, PP mesh, metallic mesh |

| Micron rating |

50μm - 300μm |

|

Mesh parts fabrication |

Laser cutting, sonic cutting, sonic welding, heat welding |

| Process |

Mesh insert injection moulding |

| Specification |

Custom |

| Colour |

Custom |

Nylon Filter Mesh Specification For Homemade Cheese Separator Filter

Fabric

number |

Mest count |

Thread

diameter |

Mesh

opening |

Open

surface |

Fabric

thickness |

Weight |

| No. |

mesh/cm |

mesh/inch |

micron |

micron |

% |

micron |

g/m2 |

| JPP12 |

12 |

30 |

250 |

583 |

49 |

470 |

162 |

| JPP12 |

12 |

30 |

300 |

533 |

41 |

585 |

234 |

| JPP14 |

14 |

35 |

300 |

414 |

34 |

595 |

273 |

| JPP16 |

16 |

40 |

200 |

425 |

46 |

370 |

139 |

| JPP16 |

16 |

40 |

250 |

375 |

36 |

485 |

217 |

| JPP20 |

20 |

50 |

150 |

350 |

49 |

375 |

98 |

| JPP20 |

20 |

50 |

200 |

300 |

36 |

385 |

173 |

| JPP24 |

24 |

60 |

150 |

267 |

41 |

285 |

117 |

| JPP28 |

28 |

70 |

120 |

237 |

44 |

215 |

87 |

| JPP30 |

30 |

76 |

120 |

213 |

41 |

225 |

94 |

| JPP32 |

32 |

80 |

100 |

213 |

46 |

165 |

69 |

| JPP36 |

36 |

90 |

100 |

178 |

41 |

178 |

78 |

| JPP40 |

40 |

100 |

100 |

150 |

36 |

190 |

87 |

| JPP43 |

43 |

110 |

80 |

152 |

43 |

135 |

60 |

| JPP48 |

48 |

120 |

80 |

130 |

38 |

145 |

62 |

| JPP56 |

56 |

140 |

60 |

120 |

44 |

85 |

44 |

| JPP59 |

59 |

150 |

60 |

110 |

42 |

98 |

46 |

| JPP64 |

64 |

160 |

60 |

100 |

37 |

105 |

50 |

| JPP72 |

72 |

180 |

50 |

90 |

41 |

82 |

39 |

| JPP80 |

80 |

200 |

50 |

75 |

36 |

90 |

43 |

| JPP100 |

100 |

250 |

42 |

60 |

36 |

65 |

35 |

| JPP120 |

120 |

305 |

30 |

55 |

42 |

52 |

20 |

| JPP120 |

120 |

305 |

35 |

45 |

29 |

60 |

28 |

| JPP120 |

120 |

305 |

38 |

42 |

25 |

67 |

35 |

| JPP120 |

120 |

305 |

42 |

42 |

25 |

75 |

42 |

How To Select The Filter Mesh?

You can follow these points.

- Mesh size or the size of the particle you need to filter

- Mesh material (consider the working condition)

- Mesh thread diameter, Mesh thickness

- Opening area

Custom Filter Elements in Mesh Filter Fabric

At Share Filters, we can customize our filter elements through three main processes :

- Cutting: in all possible shapes .

- Assembly on a support: the mesh filter that has been previously cut is then assembled by ultrasonic welding on a flexible, semi-rigid or rigid support.

- Filter molding: the filter mesh is molded by injection molding.

Share Filters OEM Plastic Moulded Filters

Why Work With Share Filters ?

Share Filters specializes in helping our customers design and manufacture high quality mesh filter components to around the world. As a supplier combining the woven filter mesh manufacturing and mesh processing according to custom-made design, we are flexible enough to adapt to our customers’ production and delivery needs. Our advanced manufacturing processes and scientific machines allow us to create filtration products in any shape or configuration – from simple, traditional components like mesh shapes to highly complex devices like custom plastic filters.

Our customers typically work in the fields of food technology, motor equipment, water treatment, healthcare, semiconductor technology, automotive, medicine and pharmaceuticals. We also supply institutes, laboratory facilities or private end custom

There are many ways to make a filtration product. Share Filter Can Offer the Nylon Filter Mesh in Different Types to meet customs' different demands.

Nylon Filter Mesh in Rolls

The width of nylon filter mesh rolls can be in 100cm, 127cm, 150cm, 160cm, 175cm, 183cm, 365cm or other custom width.

Length can be 30m, 50m, 70m, or other custom length.

Nylon Filter Mesh in Narrow Strips

Share Filters slitting is also used for manufacturing fabric strips and produces a closed edge with very little material build up at the edge.

Nylon Filter Mesh in Cutted Shapes.

Our cutting method include Laser cutting, Cold cutting, Hot cutting, Slitting, Punching. Professional cutting using custom made tools that will not damage the materials.

Nylon Filter Mesh In Tubes

Sonic welding are accurate, clean. Lapping welding strength to some degree.

Custom Nylon Filter Mesh Bags

Share Filters has standard filter bags with galvanized steel or plastic rings, which are sewn or welded, made of regenerable monofilament filter cloth from 3 micron to 2000 microns or felt from 0.5 microns to 200 microns.

Mesh Insert Plastic Injection Molded Filters

Our injection moulded filters products consist of a synthetic filter mesh held in a polymer plastic frame, allowing for a more robust part/product giving more reliability and longevity in its use.

Photos of Share Filters Workshops

If you want a mesh insert filters manufacturing partner capable of providing you with the experience support system, look no further than Taizhou Share Filters Co., Ltd.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!