Product Description

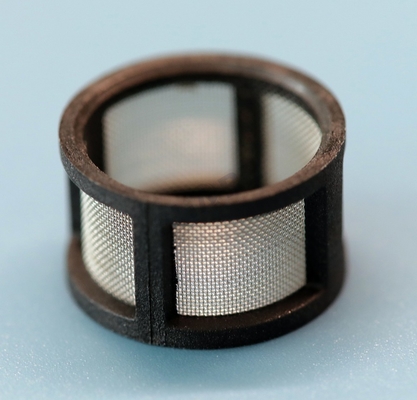

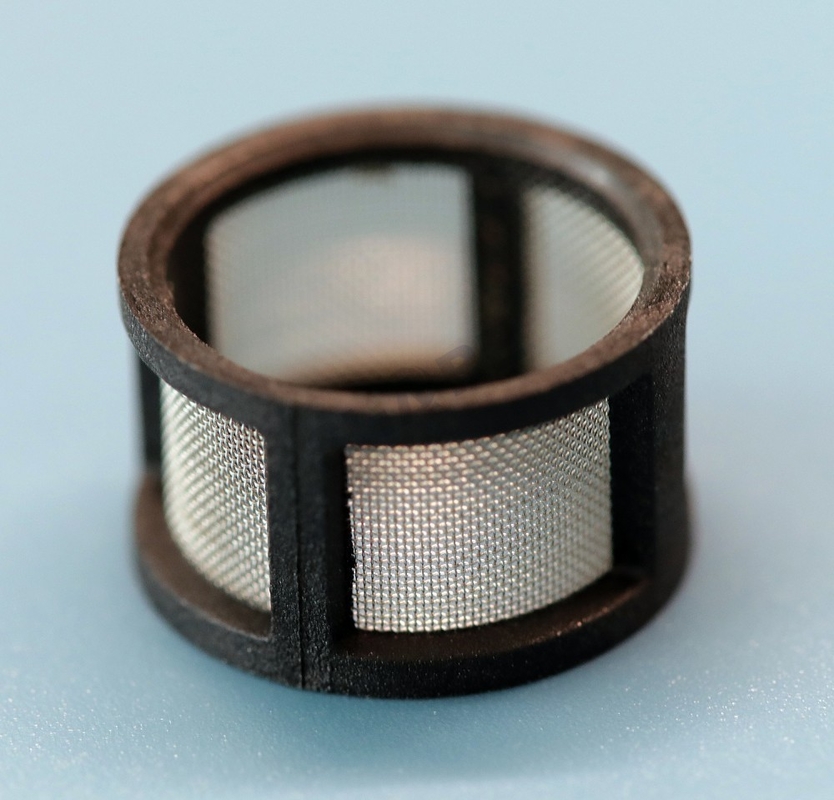

Commercial Water Heating Filter Element Heat-Resisting Polyester Mesh Strainer

A water heating filter is a device used to remove impurities and sediment from the water supply before it reaches a water heater. It is installed on the water inlet line of the heater and helps protect the heating elements and other internal components from damage caused by debris and scale buildup.

Share Filters' insert moulded water heating filter consist of a polyester filter mesh or stainless steel mesh held in a polymer plastic frame, allowing for a more robust part giving more reliability and longevity in its use. Injection moulding can take many forms and Share Filters is fully capable to help develop and produce the injection moulded filter product according to your drawing that will best suit your needs, as well as, offering any additional advice or service along the way.

Share Filtes Water Heating Filter Materials Options

|

Support rim material |

PA, PET, PP, PE, ABS, POM, and other high- performance thermoplastics |

| Filter media |

Polyester, nylon mesh, polyester mesh, PP mesh, stainless steel mesh, brass mesh |

| Micron rating |

100μm - 600μm |

|

Mesh parts fabrication |

Slitting, cutting, welding |

| Process method |

Mesh insert injection moulding |

| Specification |

Custom |

| Colour |

Custom |

Polyester(PET) Filter Mesh Specification

Fabric

number |

Mesh count |

Thread

diameter |

Mesh

opening |

Open

surface |

Fabric

thickness |

Weight |

| No. |

mesh/cm |

mesh/inch |

micron |

micron |

% |

micron |

g/m2 |

| PES 680/67 |

12 |

30 |

150 |

680 |

67 |

260 |

69 |

| PES 580/48 |

12 |

30 |

250 |

580 |

48 |

460 |

192 |

| PES 530/40 |

12T |

30 |

300 |

530 |

40 |

580 |

277 |

| PES 515/52 |

14S |

36 |

200 |

515 |

52 |

360 |

143 |

| PES 470/50 |

15S |

38 |

200 |

470 |

50 |

380 |

154 |

| PES 420/40 |

15T |

38 |

250 |

420 |

40 |

470 |

240 |

| PES 525/92 |

16S |

41 |

100 |

525 |

92 |

180 |

36 |

| PES 425/46 |

16T |

41 |

200 |

425 |

46 |

380 |

164 |

| PES 405/53 |

18S |

46 |

150 |

405 |

53 |

260 |

104 |

| PES 375/46 |

18T |

46 |

180 |

375 |

46 |

330 |

150 |

| PES 375/51 |

19T |

48 |

150 |

375 |

51 |

260 |

110 |

| PES 420/71 |

20S |

50 |

80 |

420 |

71 |

140 |

33 |

| PES 400/64 |

20S |

50 |

110 |

400 |

64 |

180 |

51 |

| PES 350/49 |

20T |

50 |

150 |

350 |

49 |

260 |

115 |

| PES 325/47 |

21T |

53 |

150 |

325 |

47 |

270 |

121 |

| PES 340/67 |

24S |

61 |

120 |

340 |

67 |

220 |

88 |

| PES 270/42 |

24T |

61 |

150 |

270 |

42 |

280 |

138 |

| PES 250/46 |

27T |

68 |

120 |

250 |

46 |

230 |

100 |

| PES 280/62 |

28S |

71 |

80 |

280 |

62 |

150 |

46 |

| PES 240/45 |

28T |

71 |

120 |

240 |

45 |

230 |

103 |

| PES 225/43 |

29T |

74 |

120 |

225 |

43 |

230 |

107 |

| PES 215/42 |

30T |

76 |

120 |

215 |

42 |

230 |

111 |

| PES 230/54 |

32S |

80 |

80 |

230 |

54 |

150 |

52 |

| PES 210/45 |

32T |

80 |

100 |

210 |

45 |

180 |

82 |

| PES 215/53 |

34S |

86 |

80 |

215 |

53 |

150 |

56 |

| PES 195/44 |

34T |

86 |

100 |

195 |

44 |

180 |

87 |

| PES 180/42 |

36T |

91 |

100 |

180 |

42 |

180 |

92 |

| PES 200/61 |

39S |

99 |

55 |

200 |

61 |

95 |

30 |

| PES 190/55 |

39T |

99 |

64 |

190 |

55 |

115 |

40 |

| PES 150/36 |

40T |

102 |

100 |

150 |

36 |

190 |

103 |

| PES 150/42 |

43T |

110 |

80 |

150 |

42 |

155 |

71 |

| PES 160/57 |

47S |

120 |

55 |

160 |

57 |

96 |

36 |

| PES 150/50 |

47T |

120 |

64 |

150 |

50 |

120 |

48 |

| PES 140/43 |

47HD |

120 |

71 |

140 |

43 |

130 |

59 |

| PES 140/47 |

49S |

125 |

64 |

140 |

47 |

120 |

50 |

| PES 135/44 |

49T |

125 |

71 |

135 |

44 |

130 |

62 |

| PES 144/55 |

53S |

135 |

45 |

144 |

55 |

76 |

27 |

| PES 135/51 |

53S |

135 |

55 |

135 |

51 |

97 |

40 |

| PES 125/44 |

53T |

135 |

64 |

125 |

44 |

122 |

54 |

| PES 117/39 |

53T |

135 |

71 |

117 |

39 |

132 |

67 |

| PES 115/46 |

59S |

150 |

55 |

115 |

46 |

99 |

45 |

| PES 105/38 |

59T |

150 |

64 |

105 |

38 |

123 |

61 |

| PES 100/41 |

64S |

160 |

55 |

100 |

41 |

100 |

48 |

Customer Benefits From Share Filters Mesh Insert injection Moulded Filters

Optimized part design.

The part design of your filter screen is optimized for the injection moulding process. The mesh material is correctly "embedded" in the thermoplastic.

Suitable material selection.

The plastic and filter mesh is designed for your part and application.

Process stability

A stable plastic injection moulding process thanks to feasibility study and test.

Advanced production equipments

Compliance with quality specifications and documentation thanks to advanced production equipments and technology.

Other OEM Plastic Moulded Filters

Mesh Filters Selection and Sizing

Share Filters has over 20 years of experience developing and manufacturing filter mesh and custom screen and filtration solutions. We help customers size and select the best filtration product to ensure years of trouble free operation and return on investment.

We insert and over mould synthetic filter mesh as well as metallic mesh for Moulded Filter Components. These components are used in a multitude of industries ranging from water applications to multiple automotive applications, white house applications and medical applications.

Share Filters have a variety of manufacturing processes at our facility. Our current capabilities include filter mesh weaving, mesh slitting, laser die cutting, punching, heat welding, sonic welding, horizontal and vertical injection molding, etc.

Share Filters Factory Capabilities

| Synthetic Mesh |

Slitting |

Cutting |

Welding |

Sewing |

Injection Moulding |

|

|

|

|

|

|

| Share Filters synthetic meshes can be made from a variety of materials such as polyamide, polyester, polypropylene, etc. You can order by the roll or cut shape. |

Ultrasonic slitting is also used for manufacturing fabric strips and produces a closed edge with very little material build up at the edge. |

Our cutting method include Laser cutting, Cold cutting, Hot cutting, Slitting, Stamping. Professional cutting using custom made tools that will not damage the materials. |

Sonic welding are accurate, clean. Precision sleeves and bags for blood filtration, rosin bag for rosin press are examples of applications that benefit from this technology. |

Share Filters sewing products are carried out by highly skilled and experienced machinists, which ensure you get the right level of consistent quality. |

Custom plastic molded filter combine precise filter mesh with polymer plastic. Industry serve: Automotive, Appliances, Food and beverage, Medical, Life Science and Laboratory. |

Contact us

Please connect with us so we can learn more about your application and design specifications!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!