Product Description

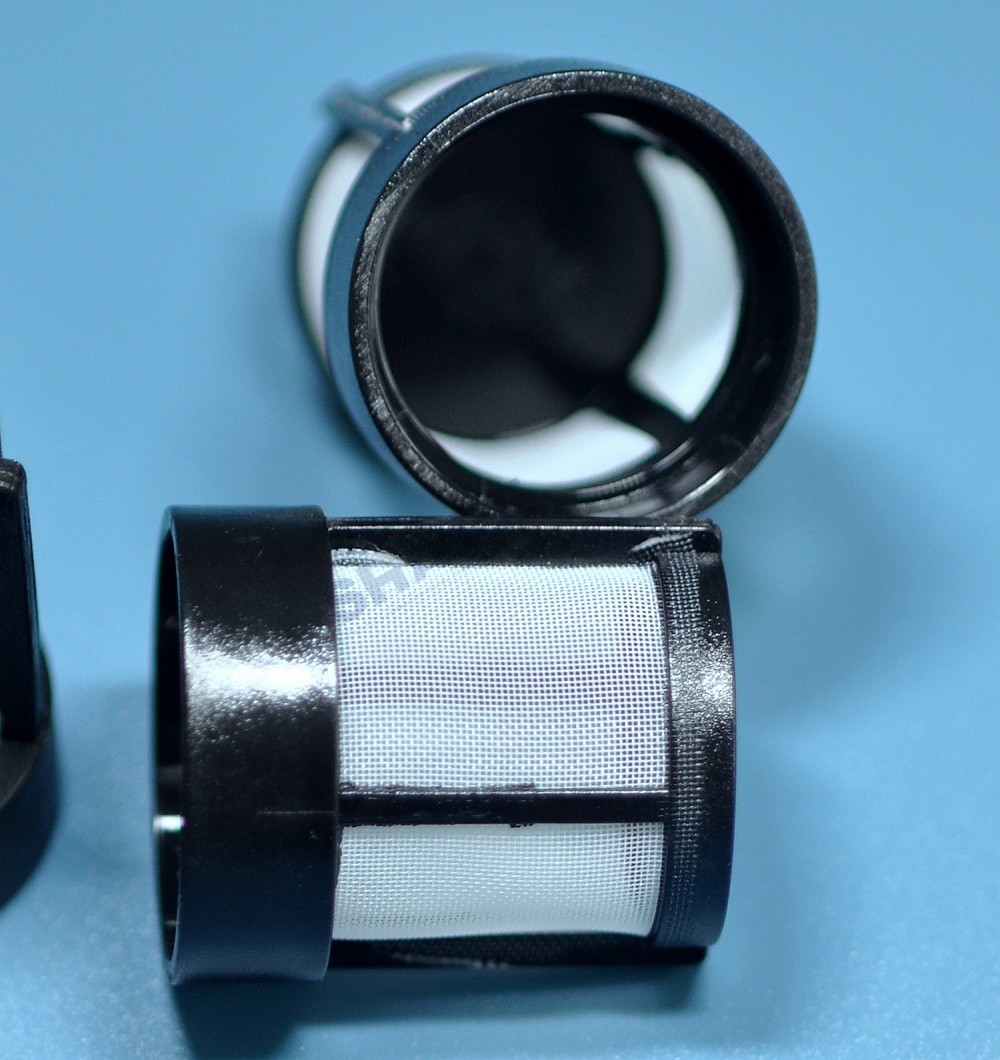

Motor In-Tank Fuel Pump Strainer Nylon Mesh 60 Micron OEM Plastic Molded Filter

The fuel pump strainer is a fuel system's first line of defense against fuel system contamination; including dirt, dust, or other fine particles floating around in the gas.

Share Filters' injection moulded fuel pump strainers consist of a nylon or polyester filter mesh held in a polymer plastic frame, allowing for a more robust part/product giving more reliability and longevity in its use. Injection moulding can take many forms and Share Filters is fully capable to help develop and produce the injection moulded filter product that will best suit your needs, as well as, offering any additional advice or service along the way.

Share Filters Mesh Insert Injection Molded Fuel Pump Filter Options

| Product Name |

Motor in-tank fuel pump strainer with nylon mesh 60 micron |

| Application |

Automotive, Motorcycle, Construction machine |

| Filter Media |

Nylon filter mesh, polyester filter, stainless steel mesh |

| Micron Rating |

25μm - 300μm |

| Suport cage |

PA, PE, PC, PP, ABS, POM, etc. |

| Dimension |

Custom size |

What Is a Plastic Molded Filter ?

Plastic molded mesh filters / insert molded filters, as the name implies, are made via insert molding. This is the process injecting liquid resin into a mold. In the case of resin molded filters, the liquid resin bonds with filter mesh inside the mold.

Plastic molded filters are a precision, cost effective and convenient filtration solution. They can be made in just about any size or shape, making them very useful for a wide variety of custom applications– engine oil filters, water filters, medical device filters, washing filter and many, many more.

Nylon Filter Mesh Specification For Fuel Pump Strainer

Fabric

number |

Mest count |

Thread

diameter |

Mesh

opening |

Open

surface |

Fabric

thickness |

Weight |

| No. |

mesh/cm |

mesh/inch |

micron |

micron |

% |

micron |

g/m2 |

| JPP20 |

20 |

50 |

150 |

350 |

49 |

375 |

98 |

| JPP20 |

20 |

50 |

200 |

300 |

36 |

385 |

173 |

| JPP24 |

24 |

60 |

150 |

267 |

41 |

285 |

117 |

| JPP28 |

28 |

70 |

120 |

237 |

44 |

215 |

87 |

| JPP30 |

30 |

76 |

120 |

213 |

41 |

225 |

94 |

| JPP32 |

32 |

80 |

100 |

213 |

46 |

165 |

69 |

| JPP36 |

36 |

90 |

100 |

178 |

41 |

178 |

78 |

| JPP40 |

40 |

100 |

100 |

150 |

36 |

190 |

87 |

| JPP43 |

43 |

110 |

80 |

152 |

43 |

135 |

60 |

| JPP48 |

48 |

120 |

80 |

130 |

38 |

145 |

62 |

| JPP56 |

56 |

140 |

60 |

120 |

44 |

85 |

44 |

| JPP59 |

59 |

150 |

60 |

110 |

42 |

98 |

46 |

| JPP64 |

64 |

160 |

60 |

100 |

37 |

105 |

50 |

| JPP72 |

72 |

180 |

50 |

90 |

41 |

82 |

39 |

| JPP80 |

80 |

200 |

50 |

75 |

36 |

90 |

43 |

| JPP100 |

100 |

250 |

42 |

60 |

36 |

65 |

35 |

| JPP120 |

120 |

305 |

30 |

55 |

42 |

52 |

20 |

| JPP120 |

120 |

305 |

35 |

45 |

29 |

60 |

28 |

| JPP120 |

120 |

305 |

38 |

42 |

25 |

67 |

35 |

| JPP120 |

120 |

305 |

42 |

42 |

25 |

75 |

42 |

This data sheet just include our common specification, please contact us if you have other custom specification

Share Filters provide one-stop filter solution, like filter media, filter mesh shapes, filter mesh tubes, mesh insert injection molded filters.

Filter mesh Mesh shapes Filter mesh tube Molded filter

Many of our custom filtration product solutions are molded from mesh and plastic, utilizing our insert injection molding or pot molding capabilities. These processes allow for flexibility in design and material selection. They also offer significant advantages in cost and ease of manufacture over other potential solutions.

We insert and over mold synthetic mesh, stainless steel wires as well as other metalic mesh for molded filter components. These components are used in a multitude of industries ranging from water applications to multiple automotive applications, small engine applications and medical applications.

Application of Share Molded Filters

|

|

|

|

|

| Automotive |

Irrigation |

Food |

Appliance |

Health care |

Contact us, if you have filtration enquiry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!