Product Description

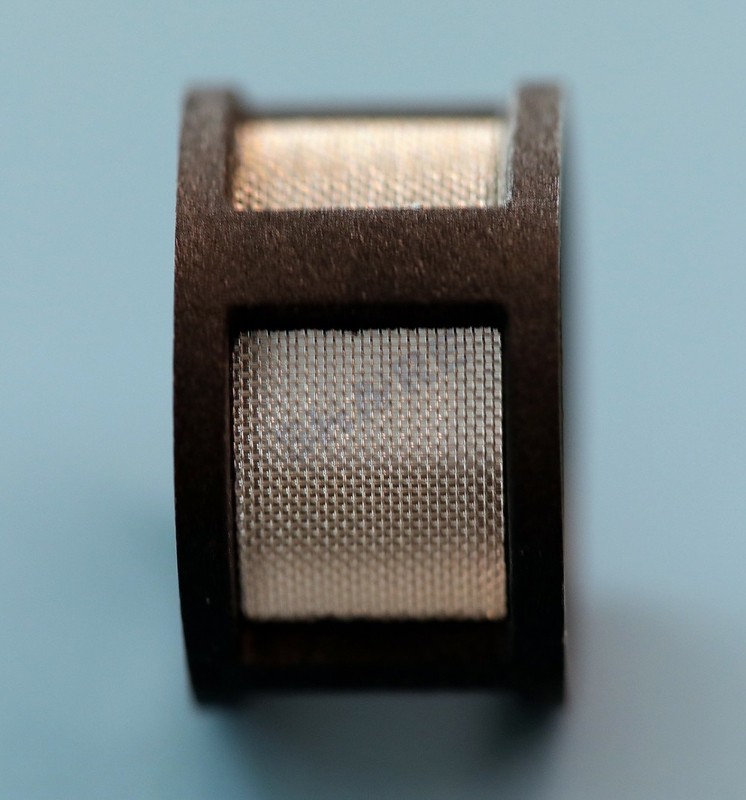

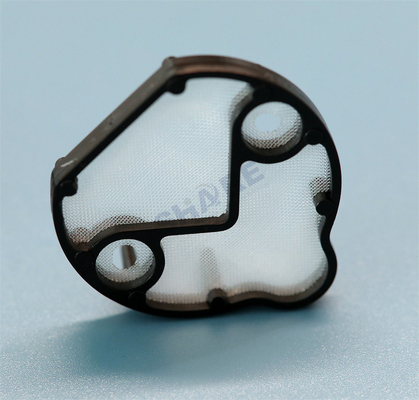

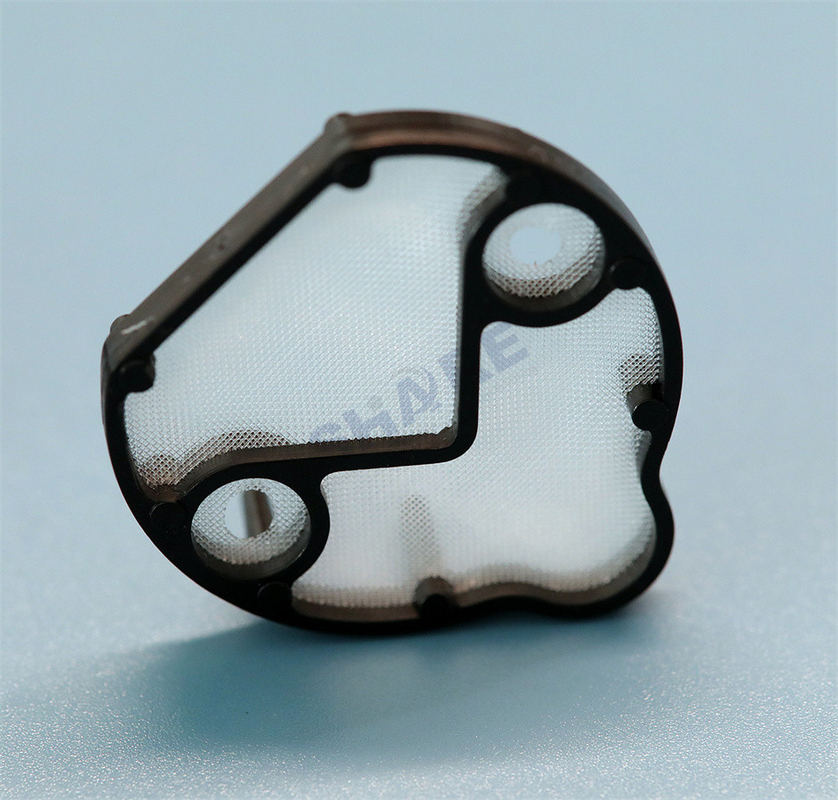

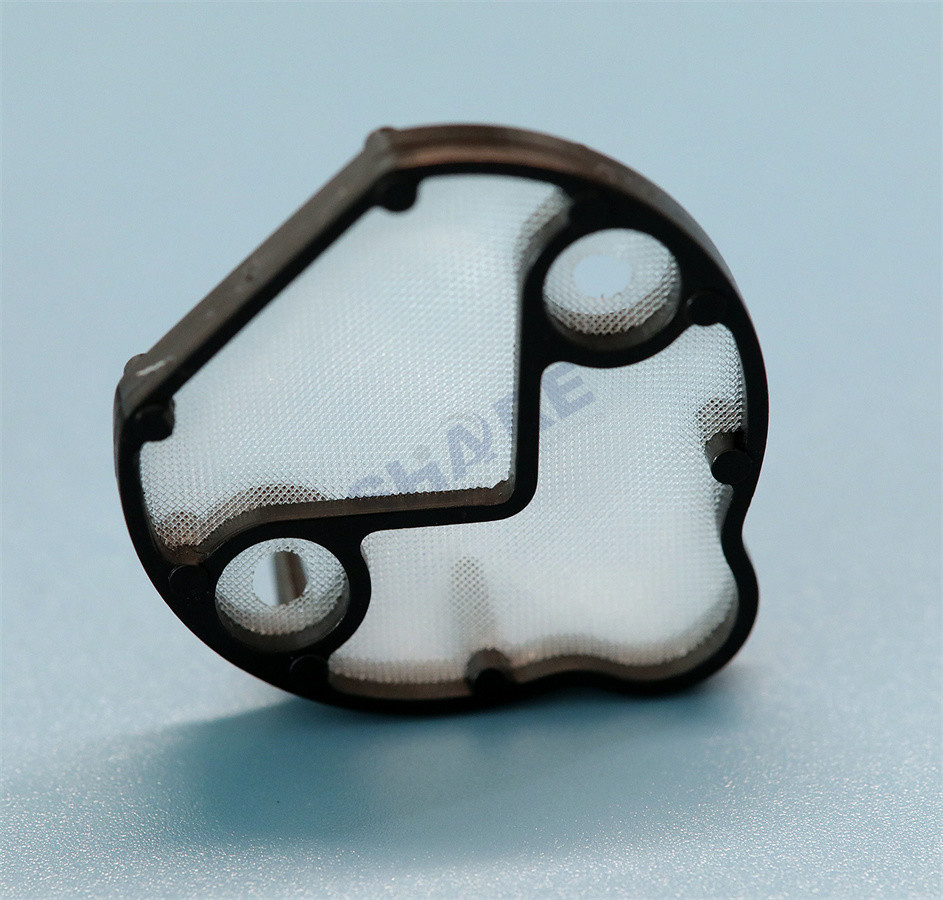

OEM Automobile Transmission Valve Body Internal Filter With Wire Screen

The Valve body internal filter is designed to capture and remove contaminants, such as dirt, debris, and metal particles, from the automatic transmission fluid as it circulates through the valve body. It helps ensure that the transmission operates smoothly and efficiently by preventing these contaminants from entering the sensitive components of the transmission.

Share Filters' OEM injection moulded valve filters consist of a stainless steel mesh or synthetic filter mesh held in a polymer frame, allowing for a more robust part/product giving more reliability and longevity in its use. Injection moulding can take many form and shape, Share Filters is fully capable to help develop and produce the injection moulded filter product that will best suit our cuatomers' needs, as well as, offering any additional advice or service in every stage, from the material selection to final products.

Technical Data

| Product name: |

Transmission filter |

Rim material: |

ABS, PP, PA, PE, etc. |

| Application: |

Automobile transmission valve body |

Mesh: |

Stainless steel mesh, nylon mesh, PET mesh |

| OEM: |

Acceptable |

Micron rating: |

From 25μm to 500μm |

| Processing: |

Mesh insert injection moulding |

Color: |

Customize |

| Dimension: |

Customize |

Package: |

Plastic bag, master carton |

Product Picture

Injection Moulding Process

Injection moulding can provide a part or product that carries a more complex shape for more specific functionality, as well as, still being cost-effective and able to be produced in larger numbers consistently and within a deadline.

Share Filters OEM Filters for Automobile

Property of Thermoplastic

| PA6 (polyamide 6) |

Tough, abrasion-resistant, good vibration damping, resistant to solvents, fuels and lubricant |

| PA66 (polyamide6.6) |

Rigid, stiff, abrasion-resistant, dimensionally stable at heat exposure. |

| PET (polyethyleneterehthalate) |

High rigidity, high hardness, high chemical resistance, good dimensional stability. |

| PP (polypropylene) |

Good chemical resistance, more heat resistant than PVC

|

| ABS (Acrylonitrile Butadiene Styrene) |

Toughness and impact resistance, good stiffness and machinability even at low temperatures. |

Stainless Steel Filter Mesh Datasheet

| Mesh Count (per inch) |

Thread Diameter (microns) |

Aperture |

Open Area (%) |

Weight (IB) /100 Square Foot |

| |

inch |

mm |

inch |

mm |

|

|

| 8x8 |

0.028 |

0.71 |

0.097 |

2.46 |

60.2 |

41.1 |

| 10x10 |

0.025 |

0.64 |

0.075 |

1.91 |

56.3 |

41.2 |

| 10x10 |

0.020 |

0.51 |

0.080 |

2.03 |

64.0 |

26.1 |

| 12x12 |

0.023 |

0.584 |

0.060 |

1.52 |

51.8 |

42.2 |

| 12x12 |

0.020 |

0.508 |

0.063 |

1.60 |

57.2 |

31.6 |

| 14x14 |

0.023 |

0.584 |

0.048 |

1.22 |

45.2 |

49.8 |

| 14x14 |

0.020 |

0.508 |

0.051 |

1.30 |

51.0 |

37.2 |

| 16x16 |

0.018 |

0.508 |

0.0445 |

1.13 |

50.7 |

34.5 |

| 18x18 |

0.017 |

0.432 |

0.0386 |

0.98 |

48.3 |

34.8 |

| 20x20 |

0.020 |

0.508 |

0.0300 |

0.76 |

36.0 |

55.2 |

| 20x20 |

0.016 |

0.406 |

0.0340 |

0.86 |

46.2 |

34.4 |

| 24x24 |

0.014 |

0.356 |

0.0277 |

0.70 |

44.2 |

31.8 |

| 30x30 |

0.013 |

0.330 |

0.0203 |

0.52 |

37.1 |

34.8 |

| 30x30 |

0.012 |

0.305 |

0.0213 |

0.54 |

40.8 |

29.4 |

| 30x30 |

0.009 |

0.229 |

0.0243 |

0.62 |

53.1 |

16.1 |

| 35x35 |

0.011 |

0.279 |

0.0176 |

0.45 |

37.9 |

29.0 |

| 40x40 |

0.010 |

0.254 |

0.0150 |

0.38 |

36.0 |

27.6 |

| 50x50 |

0.009 |

0.229 |

0.0110 |

0.28 |

30.3 |

28.4 |

| 50x50 |

0.008 |

0.203 |

0.0120 |

0.31 |

36.0 |

22.1 |

| 60x60 |

0.0075 |

0.191 |

0.0092 |

0.23 |

30.5 |

23.7 |

| 60x60 |

0.007 |

0.178 |

0.0097 |

0.25 |

33.9 |

20.4 |

| 70x70 |

0.0065 |

0.165 |

0.0078 |

0.20 |

29.8 |

20.8 |

| 80x80 |

0.0065 |

0.165 |

0.0060 |

0.15 |

23.0 |

23.2 |

| 80x80 |

0.0055 |

0.140 |

0.0070 |

0.18 |

31.4 |

16.9 |

| 90x90 |

0.005 |

0.127 |

0.0061 |

0.16 |

30.1 |

15.8 |

| 100x100 |

0.0045 |

0.114 |

0.0055 |

0.14 |

30.3 |

14.2 |

| 100x100 |

0.004 |

0.102 |

0.0060 |

0.15 |

36.0 |

11.0 |

| 100x100 |

0.0035 |

0.089 |

0.0065 |

0.17 |

42.3 |

8.3 |

| 110x110 |

0.0040 |

0.1016 |

0.0051 |

0.1295 |

30.7 |

12.4 |

| 120x120 |

0.0037 |

0.0940 |

0.0064 |

0.1168 |

30.7 |

11.6 |

| 150x150 |

0.0026 |

0.0660 |

0.0041 |

0.1041 |

37.4 |

7.1 |

| 160x160 |

0.0025 |

0.0635 |

0.0038 |

0.0965 |

36.4 |

5.94 |

| 180x180 |

0.0023 |

0.0584 |

0.0033 |

0.0838 |

34.7 |

6.70 |

| 200x200 |

0.0021 |

0.0533 |

0.0029 |

0.0737 |

33.6 |

6.2 |

| 250x250 |

0.0016 |

0.0406 |

0.0024 |

0.0610 |

36.0 |

4.4 |

| 270x270 |

0.0016 |

0.0406 |

0.0021 |

0.0533 |

32.2 |

4.7 |

| 300x300 |

0.0015 |

0.0381 |

0.0018 |

0.0457 |

29.7 |

3.04 |

| 325x325 |

0.0014 |

0.0356 |

0.0017 |

0.0432 |

30.0 |

4.40 |

| 400x400 |

0.0010 |

0.0254 |

0.0015 |

0.370 |

36.0 |

3.32 |

| 500x500 |

0.0010 |

0.0254 |

0.0010 |

0.0254 |

25.0 |

3.80 |

| 635x635 |

0.0008 |

0.0203 |

0.0008 |

0.0203 |

25.0 |

2.63 |

Share Filters, An OEM Mesh Insert Moulded Filters Manufacture From China

As a filter meshes and moulded filters manufacture, Share Filters always find the best solution is to work with our OEM customers to collaborate on their mesh filtration product development projects before the final design prints are completed. Our experienced engineers are able to not only to meet your functional requirements, but also to recommend design alterations to improve performance and manufacturability. We will concentrate on the following:

Contact Us

Share Filters provides some information for filter mesh possible applications, but there are too many functions for comprehensive descriptions of possible uses. Therefore, when considering a potential application in your particular industry, please consider contacting us who will work with engineers and product designers in choosing the right material and processing for your specific projects.

Please connect with us now so we can learn more about your application and design specifications!

What Share Filters Do?

Share Filters specializes in helping our customers design and manufacture high quality mesh filter components to around the world. As a supplier combining the filter mesh manufacturing and filter mesh processing according to custom-made design, we are flexible enough to adapt to our customers’ production and delivery needs. Our advanced manufacturing processes and scientific machines allow us to create filtration products in any shape or structure – from simple components like mesh pieces to complex devices like custom combination plastic moulded filters. Filter mesh ribbons, shapes, tube, bags, Injection-moulded filters and similar products of various shapes, sizes and fine meshes are our primary business.

We're the supplier who have experience with synthetic filter meshes and are able to use them with plastic moulding in good conditions. The molding technique requires special tools and above all a great deal of know-how. We make serial injection moulding tools, assembly preparations and procedures ourselves. Filters and parts are produced, assembled, quality controlled and packed.

Factory Capabilities

|

Precision Woven Filter Mesh in Nylon, Polyester, Polypropylene,

Selecting the high-quality monofilament thread, Share weaves filter mesh with Sulzer P7100 looms. The width of filter mesh rolls can be in 100cm, 127cm, 150cm, 165cm, 170cm, 365cm or other custom width. Length of roll can be 30m, 50m, 70m, or custom length. Mesh openings can vary from 3 micron to 4400 microns, giving these mesh filter fabrics the versatility to be used in many different liquid-solid separation processes.

|

|

Filter Mesh Slitted in Narrow Ribbons

Mesh ribbons are often the basis for various further processing steps in numerous manufacturing processes for piece, tubes and bags. A wide range of hot and ultrasonic cutting equipments enables the versatile production of ribbons from Share Filters. Share Filters ribbons are used in a multitude of applications such as automotive filters, appliances filters, industrial filters, electronic devices, healthcare.

|

|

|

Filter Mesh Pre Cut Pieces and Shapes

Share Filters cutting method include Laser cutting, Cold cutting, Heat cutting, Punching. Professional cutting using custom-made tools that will not damage the meshes. Laser cutting allows for elaborate shapes to be cut that are specific to the customer’s design needs. Laser cutting technology convinces mainly with smaller and medium quantities.

|

|

Filter Mesh Tubes and Tubular Ribbon

Share Filters offers to produce and deliver filter mesh tube parts cut to length ready for further processing. Depending on the required edge quality, different fabrication methods are available such as laser, heat , sonic or cold sectioning. With our heat and ultrasonic cutting technologies, we can create tubes equipped with one or two functional seams, which provide the necessary seam strength. These pre cut tubes are convenient for injection moulding. The ultrasonic welded tubes with one overlapping weld has more strength.

|

|

|

Custom Filter Mesh Bag by Welding and Sewing

Share Filters has the capacity to manufacture mesh filter bags by welding or sewing according to custom's design. Our full range of filter media (nylon, polyester, polypropylene) can be manufactured into bags of almost in any requested dimensions and shape. If the media is already kept in stock, we can have a quick turnaround time and can fulfil most customised orders within 7- 15 working days.

|

|

Standard Filter Bags

Share Filters produces and provides high quality liquid filter bags to fit standard size filter housing, as well as custom designed bags where requested. The constituent materials have been chosen for their purity, with consistent high quality and repeatable performance.

Top design: plastic collar, metallic ring

Filter media: filter mesh, felt

|

|

|

Mesh Insert Injection Moulded Filters

Our injection moulded filters products consist of a filter mesh held in a plastic frame. Injection moulding will drop hot plastic in a custom made mould with a synthetic or metallic mesh inside. Once cooled and solid, it can produce a very robust and reliable part or product that can be used for filters or screens.

Filtration devices with integrated mesh inserts are an effective way to keep out unwanted pollutants and contaminants. We’re a trusted manufacture of precision injection-moulded plastic parts with mesh filters for critical practices.

|

Application of Share Filters Products

Our customer base comes from a wide variety of industries including – Automotive, Home appliances, Food and beverage, Milling, Medical, Life Science and laboratory, Electronical as well as more general engineering, giving us a wealth of experience in many areas.

|

|

|

|

|

|

|

Fuel filter

|

Biopsy bag

|

Air purifier filter

|

Coffee filter

|

Irrigation filter

|

Mesh disc filter

|

| Automotive |

Laboratory |

Appliance |

Food & Beverage |

Agriculture |

Power tool |

Photos of Factory

|

| Warping |

Weaving |

Inspection |

|

| Whashing |

Heat setting |

Injection moulding |

FAQ

Are You Factory or Trade Company ?

We're factory, and manufacture our products in-house.

Where Is Your factory Located? How Can I Get There?

We are in Tiantai city, Zhejiang province China. By train, one hour away from Hangzhou and two hours away from Shanghai.

Which Port You Ship?

Ningbo port.

Can I Get Free Samples ?

We are pleased to provide you with free samples for testing, just the freight will be at your account.

When Can I Get the Quotation ?

Normally we can offer the quotation within 48 hours.

What's Your Payment Term ?

T/T, LC, PayPal, and others.

What's the Lead Time of the Order?

The production lead time is dependent on the quantity. It takes 5 to 20 working days for us to complete mass production after receive the payment.

What About Your Quality Control?

By visual inspection, optical or pressure sensitive equipment and automated 3D image-inspection equipment, our production operators conduct self-inspections at every stage of the process, from the raw material to finshed products. Additionally, we have spot inspections and final inspections carried out by our QC team.

Why Choose You ?

One of our core competencies is our excellent processing capabilities, convert the woven filter mesh to mesh ribbons, discs, shapes, tubes, bags, plastic moulded filters, with advanced equipments and professional technical team for more than 20 years. We're the few supplier who have experience with synthetic filter meshes and are able to use them with plastic moulding in good conditions.

How To Delivery the Order?

Small batch is sent by UPS, Fedex, TNT, DHL, EMS, ect, high volume will be shipped by sea and air.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!