Product Description

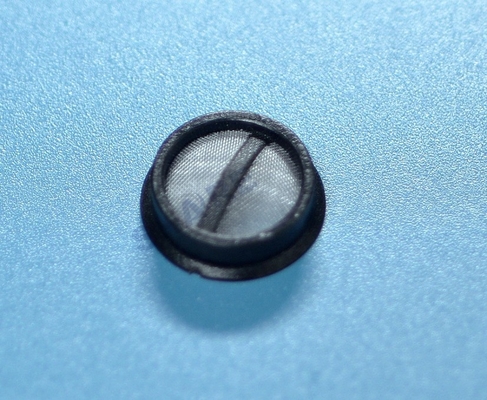

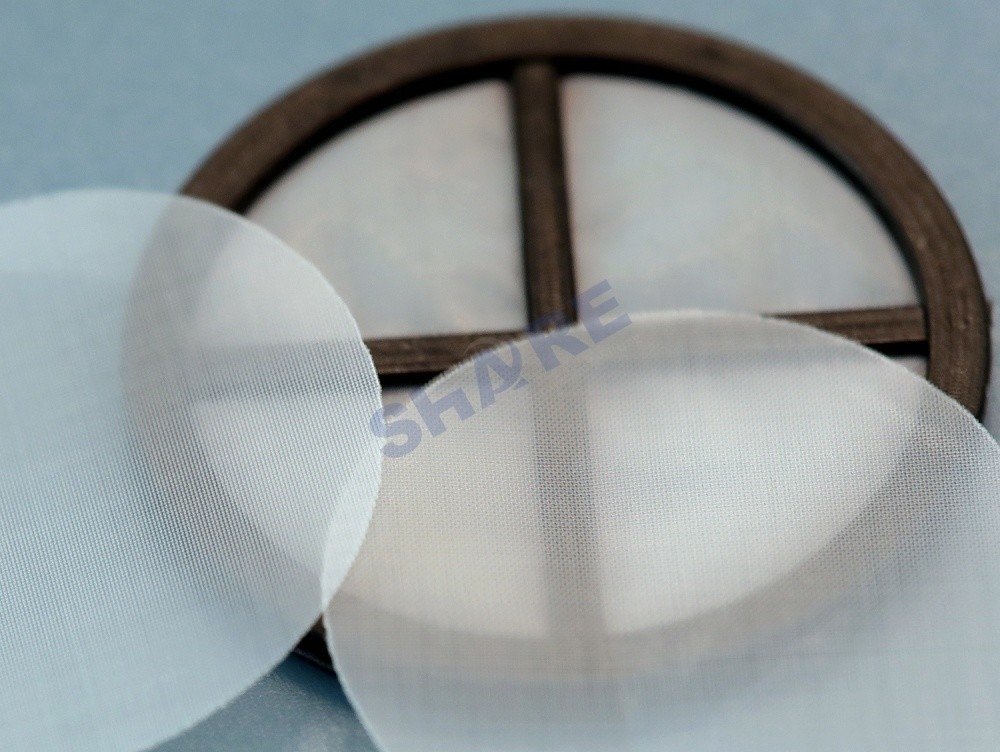

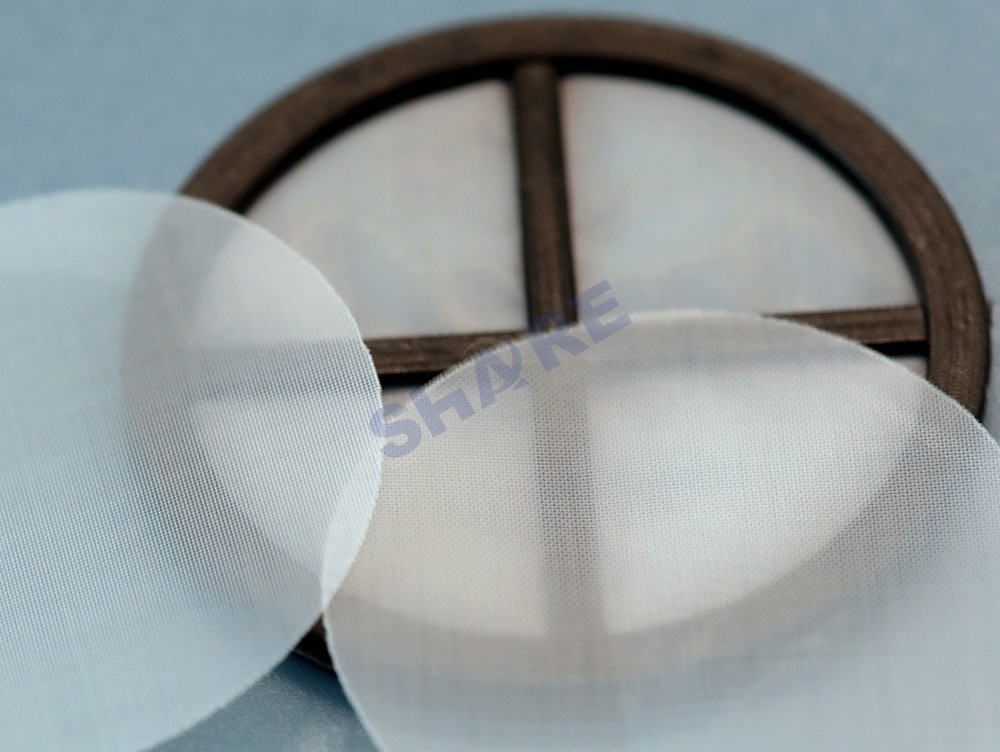

Brake System Filter For Automotive Tailored Screen And Filter

An automotive brake system filter is a component used to filter contaminants from the brake fluid in a vehicle's braking system. It is designed to prevent solid particles, debris, and other contaminants from circulating in the brake fluid and potentially causing damage to the brake components.

The brake system filter is typically located within the brake fluid reservoir or along the brake lines, depending on the specific vehicle design.

Share Filters brake filters consist of a mesh screen and polyamide rim that traps particles as the brake fluid flows through it.

|

Key Points of Brake Filters:

Contaminant Removal

Maintenance

Improve Brake Fluid Quality

Replacement Interval

Professional Service

|

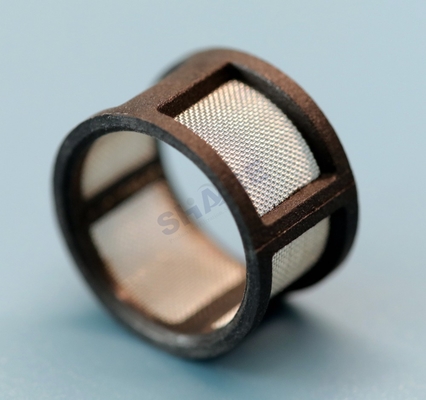

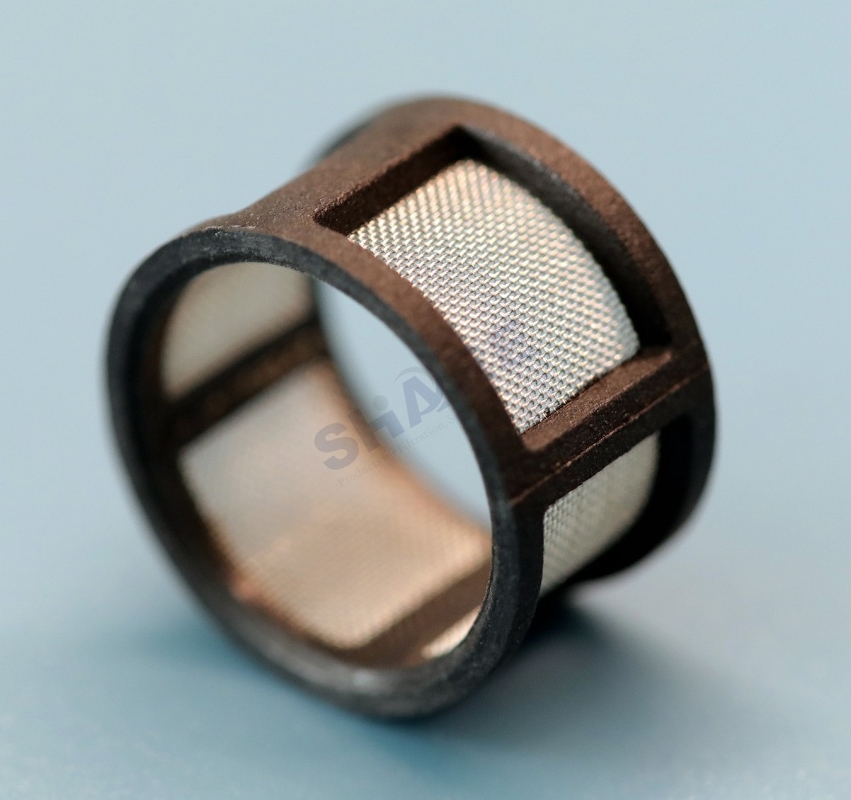

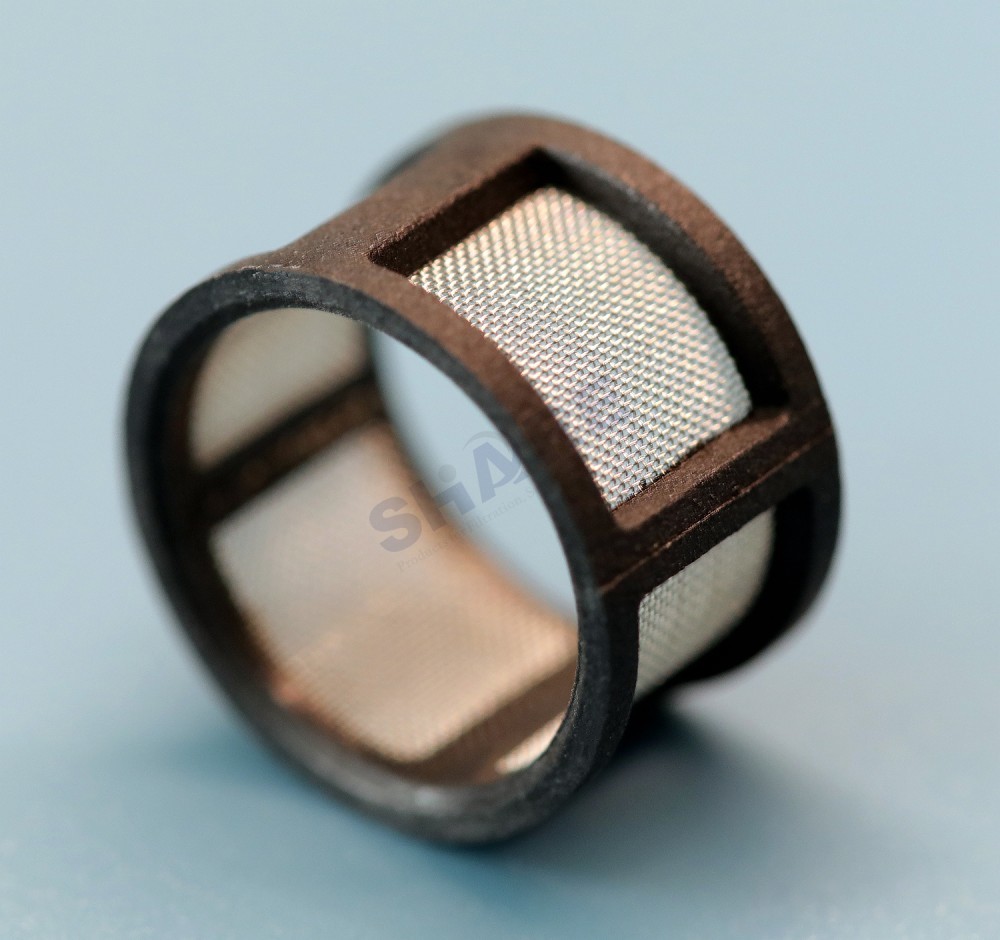

Example of Other Custom Tailored Plastic Molded Filter for Automotive

Mesh Insert Injection Moulding Process

Injection moulding can provide a part or product that carries a more complex shape for more specific functionality, as well as, still being cost-effective and able to be produced in larger numbers consistently and within a deadline.

Injection moulding will drop hot polymer plastic in a custom made mould with a synthetic mesh inside. Once cooled and solid, it can produce a very robust and reliable part or product that can be used for things such as filters or screens. By effectively fusing the polymer plastic and filter mesh, you can guarantee a higher level of integrity.

Share Filtes Injection Molding Materials Options

|

Support frame material |

PA6, PA66, PET, PP, ABS, and other High-Performance Thermoplastics |

| Filter media |

Nylon mesh, polyester mesh, PP mesh, metallic mesh |

| Micron rating |

16μm - 1500μm |

|

Mesh parts fabrication |

Laser cutting, sonic cutting, sonic welding |

| Process |

Injection moulding |

| Specification |

Custom |

| Colour |

Custom |

PA(nylon) Filter Mesh Specification

| Ref. No. |

Mesh Count |

Thread Diam. |

Mesh Opening |

Opening Area |

| |

mesh/cm |

mesh/inch |

µm |

µm |

% |

| JPP5 |

5 |

12 |

500 |

1500 |

56 |

| JPP6 |

6 |

16 |

400 |

1267 |

58 |

| JPP7 |

7 |

18 |

350 |

1079 |

57 |

| JPP8 |

8 |

20 |

350 |

900 |

52 |

| JPP9 |

9 |

24 |

250 |

860 |

60 |

| JPP10 |

10 |

25 |

300 |

700 |

49 |

| JPP12 |

12 |

30 |

250 |

583 |

49 |

| JPP12 |

12 |

30 |

300 |

533 |

41 |

| JPP14 |

14 |

35 |

300 |

414 |

34 |

| JPP16 |

16 |

40 |

200 |

425 |

46 |

| JPP16 |

16 |

40 |

250 |

375 |

36 |

| JPP20 |

20 |

50 |

150 |

350 |

49 |

| JPP20 |

20 |

50 |

200 |

300 |

36 |

| JPP24 |

24 |

60 |

150 |

267 |

41 |

| JPP28 |

28 |

70 |

120 |

237 |

44 |

| JPP30 |

30 |

76 |

120 |

213 |

41 |

| JPP32 |

32 |

80 |

100 |

213 |

46 |

| JPP36 |

36 |

90 |

100 |

178 |

41 |

| JPP40 |

40 |

100 |

100 |

150 |

36 |

| JPP43 |

43 |

110 |

80 |

152 |

43 |

| JPP48 |

48 |

120 |

80 |

130 |

38 |

| JPP56 |

56 |

140 |

60 |

120 |

44 |

| JPP59 |

59 |

150 |

60 |

110 |

42 |

| JPP64 |

64 |

160 |

60 |

100 |

37 |

| JPP72 |

72 |

180 |

50 |

90 |

41 |

| JPP80 |

80 |

200 |

50 |

75 |

36 |

| JPP100 |

100 |

250 |

40 |

60 |

36 |

| JPP120 |

120 |

305 |

40 |

43 |

25 |

| JPP130 |

130 |

330 |

40 |

37 |

23 |

| JPP140 |

140 |

355 |

30 |

38 |

33.7 |

| JPP150 |

150 |

381 |

30 |

34 |

30.25 |

| JPP165 |

165 |

420 |

30 |

28 |

20.7 |

| JPP180 |

180 |

460 |

30 |

25 |

19.5 |

| JPP200 |

200 |

510 |

30 |

16 |

10.2

|

This data sheet just include our common specification, please contact us if you have other custom specification

An OEM Mesh Insert Injection Molded Filters Manufacture From China

As a filter meshes and molded filters manufacture, Share Filters always find the best solution is to work with our OEM customers to collaborate on their mesh filtration product development projects before the final design prints are completed. Our experienced engineers are able to not only to meet your functional requirements, but also to recommend design alterations to improve performance and manufacturability.

Share Filters' Capabilities

|

|

|

|

|

|

| Share Filters synthetic meshes can be made from a variety of materials such as polyamide, polyester, polypropylene, etc. You can order by the roll or cut shape. |

Ultrasonic slitting is also used for manufacturing fabric strips and produces a closed edge with very little material build up at the edge. |

Our cutting method include Laser cutting, Cold cutting, Hot cutting, Slitting, Stamping. Professional cutting using custom made tools that will not damage the materials. |

Sonic welding are accurate, clean. Precision sleeves and bags for blood filtration, rosin bag for rosin press are examples of applications that benefit from this technology. |

Share Filters sewing products are carried out by highly skilled and experienced machinists, which ensure you get the right level of consistent quality. |

Custom plastic molded filter combine precise filter mesh with polymer plastic. Industry serve: Automotive, Appliances, Food and beverage, Medical, Life Science and Laboratory. |

We manufacture according to customer drawing as well as to sketch or sample, considering the underlying standard tolerances and customized manufacturing standards. Experience and knowledge of our employees guarantee high-quality implementation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!