Product Description

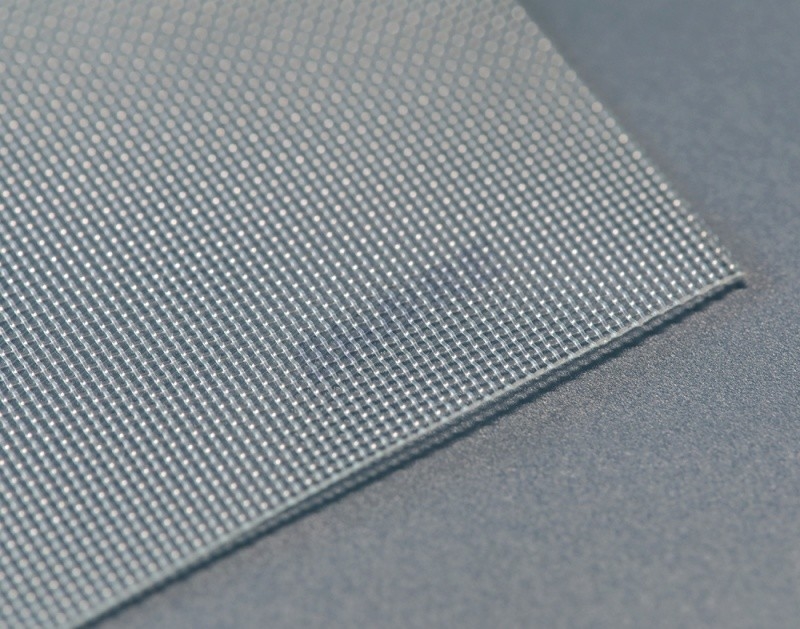

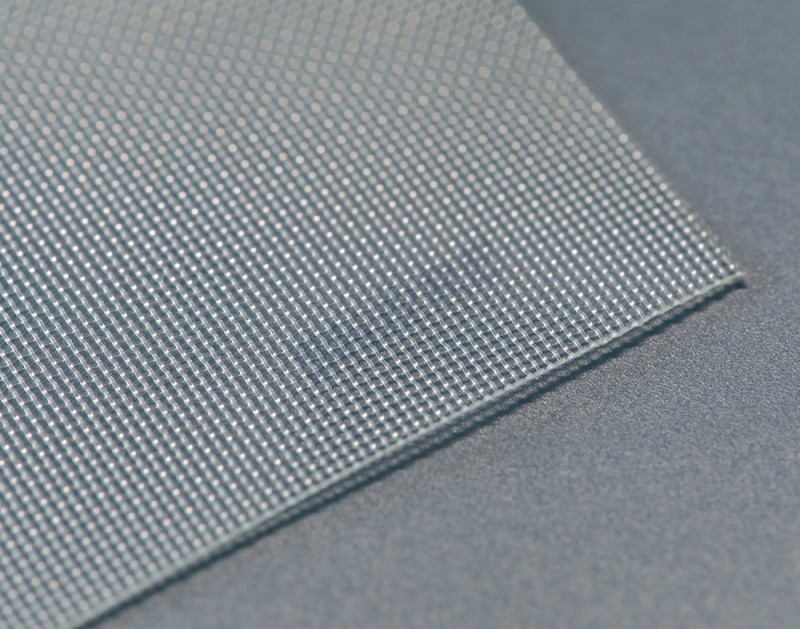

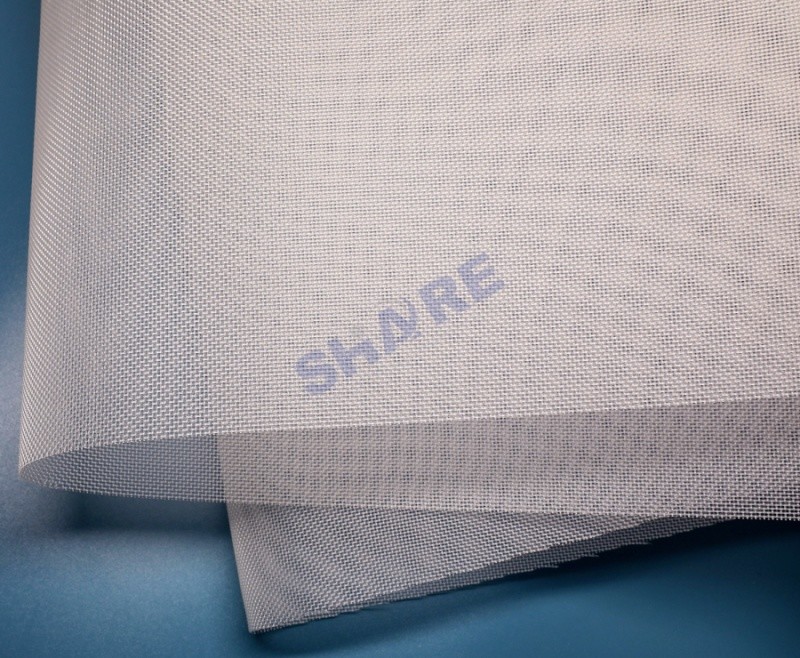

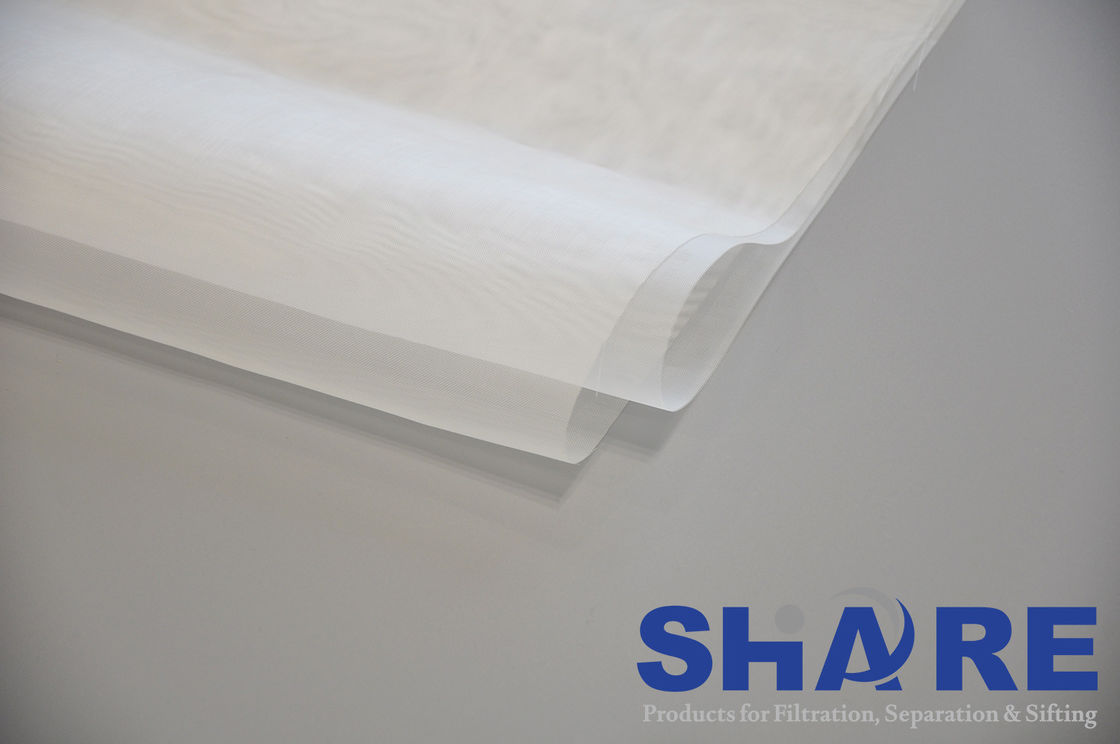

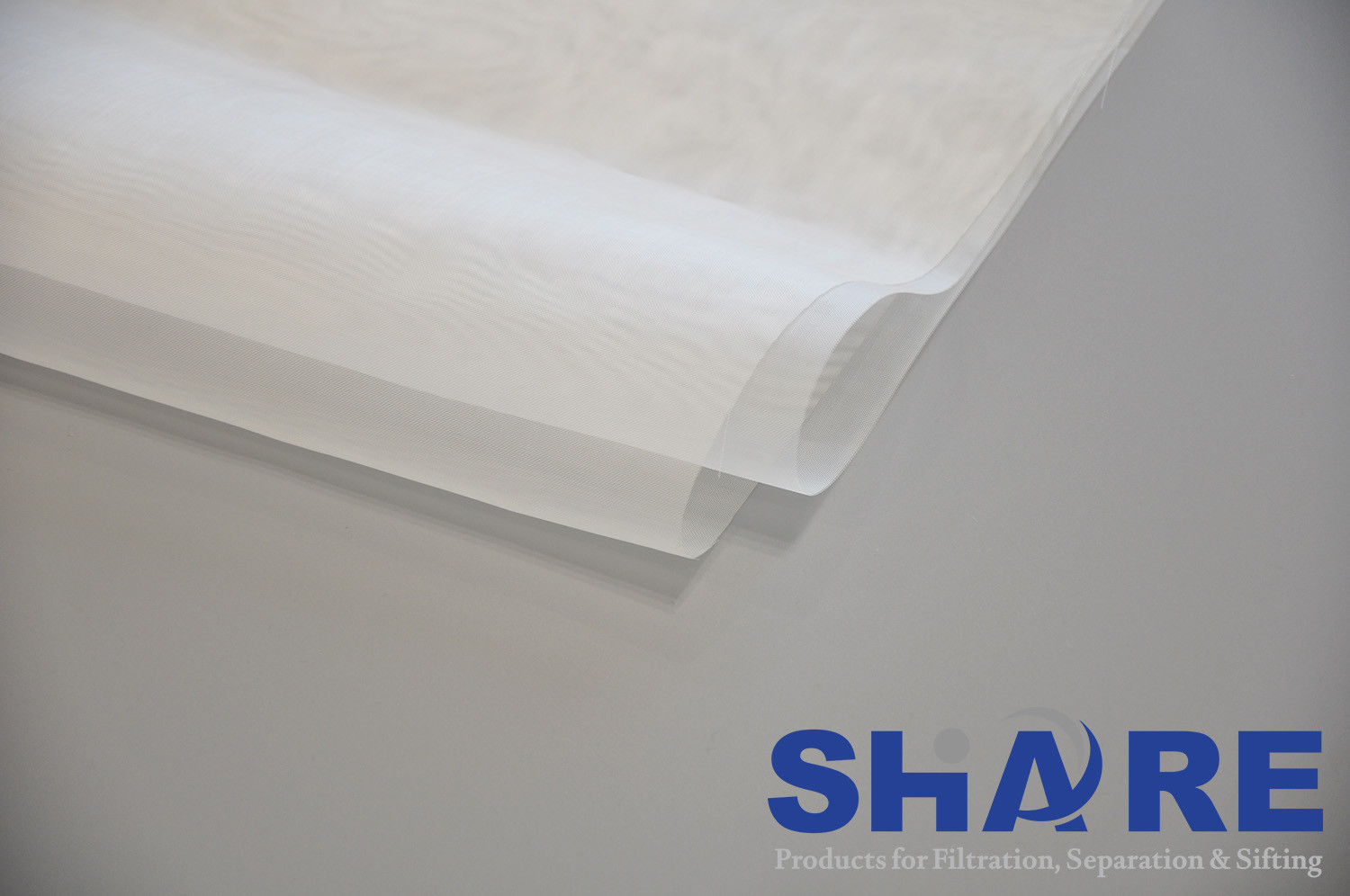

Precise Polyester Filter Mesh For Food Safety Filtration Of Food And Beverage Industry

Food products frequently undergo a crucial step called safety filtration to ensure their quality and purity before they are blended or packaged. This process serves to eliminate any unwanted and potentially harmful substances that might have unintentionally made their way into the manufacturing process. These substances can include various types of impurities such as clumps, peels, or outer coverings, as well as undesirable materials like plastic particles, cork fragments, metal fragments, bolts, screws, and tiny remnants of gaskets. Share Filters polyester filter mesh subject the food products to safety filtration, these unwanted elements are effectively removed, ensuring that the final product is free from contaminants and safe for consumption.

Polyester Filter Mesh Options for Food Safety Filtration

|

Material |

Polyester yarn |

| Application |

Food and beverage |

| Pore Size |

From 34 to 950 micron |

| Open Area |

From 12.1% to 68.2% |

| Mesh Weight |

46-169 g/sm² |

| Thread Diam |

From 34 to 300 micron |

| Dimension |

Width in 100cm, 127cm, 165cm or other customized size |

| Product Types |

Mesh rolls, shapes, tubes, bags, mesh insert injection molded filters |

A bag filter system is one of the most popular filtration methods for food liquid process applications. It provides

a versatile, cost economical and consistent filtration system suitable for a broad range of applications from

small batch operations to bulk processing.

Polyester Filter Mesh Specification Options for Food Safety Filtration

| Mesh of Count |

Type of Weave |

Thread Diameter (microns) |

Mesh Opening (microns) |

Overall Fabric Thickness (microns) |

% Open are |

Theoretical

Ink Deposit (cm³/ m²)

|

Mesh Weight (g/sm²) |

| 8/20-300W |

PW |

300 |

950 |

560 |

57.8 |

323.5 |

169 |

| 10/25-260W |

PW |

260 |

739 |

498 |

54.6 |

272.0 |

158 |

| 12/30-140W |

PW |

140 |

688 |

256 |

68.2 |

174.7 |

55 |

| 15/40-200W |

PW |

200 |

465 |

353 |

48.6 |

171.5 |

141 |

| 18/45-180w |

PW |

180 |

375 |

330 |

45.5 |

145.5 |

128 |

| 21/54-140W |

PW |

140 |

333 |

250 |

49.0 |

122.5 |

96 |

| 24/60-120W |

PW |

120 |

294 |

210 |

49.7 |

104.3 |

81 |

| 27/70-120W |

PW |

120 |

249 |

210 |

45.3 |

95.0 |

91 |

| 30/76-120W |

PW |

120 |

211 |

212 |

40.2 |

82.4 |

101 |

| 32/83-70W |

PW |

70 |

240 |

117 |

58.7 |

68.7 |

37 |

| 32/83-100W |

PW |

100 |

209 |

166 |

44.5 |

72.1 |

75 |

| 36/92-90W |

PW |

90 |

183 |

147 |

43.3 |

64.9 |

68 |

| 36/92-100W |

PW |

100 |

174 |

162 |

39.1 |

62.6 |

84 |

| 40/103-80W |

PW |

80 |

166 |

133 |

44.1 |

58.6 |

60 |

| 43/110-80W |

PW |

80 |

149 |

130 |

40.8 |

53.0 |

64 |

| 45/115-80W |

PW |

80 |

138 |

130 |

38.7 |

50.3 |

67 |

| 48/123-80W |

PW |

80 |

122 |

130 |

34.5 |

44.8 |

72 |

| 48/123-55W |

PW |

55 |

151 |

90 |

52.8 |

47.5 |

34 |

| 51/131-70W |

PW |

70 |

121 |

114 |

38.1 |

43.5 |

58 |

| 54/137-64W |

PW |

64 |

115 |

103 |

38.7 |

39.8 |

51 |

| 61/156-64W |

PW |

64 |

90 |

101 |

30.1 |

30.4 |

58 |

| 68/175-55W |

PW |

55 |

85 |

87 |

33.5 |

28.4 |

48 |

| 68/175-64W |

PW |

64 |

78 |

98 |

28.2 |

27.6 |

65 |

| 71/180-55W |

PW |

55 |

79 |

90 |

31.5 |

28.4 |

51 |

| 77/195-48W |

PW |

48 |

77 |

80 |

35.0 |

28.0 |

42 |

| 77/195-55W |

PW |

55 |

67 |

87 |

26.5 |

23.3 |

55 |

| 82/206-48W |

PW |

48 |

68 |

79 |

30.8 |

24.3 |

44 |

| 90/230-40W |

PW |

40 |

68 |

65 |

37.6 |

24.4 |

33 |

| 90/230-48W |

PW |

48 |

55 |

78 |

24.6 |

19.2 |

49 |

| 100/255-40W |

PW |

40 |

57 |

64 |

32.5 |

21.1 |

37 |

| 110/280-34W |

PW |

34 |

54 |

55 |

35.2 |

19.3 |

31 |

| 110/280-40W |

PW |

40 |

47 |

65 |

26.6 |

17.3 |

40 |

| 120/305-34W |

PW |

34 |

45 |

55 |

29.6 |

16.3 |

34 |

| 120/305-40W |

PW |

40 |

37 |

64 |

20.1 |

13.0 |

44 |

| 130/330-34W |

PW |

34 |

40 |

55 |

26.9 |

14.3 |

37 |

| 140/355-34W |

PW |

34 |

31 |

55 |

19.4 |

10.6 |

39 |

| 150/380-34W |

PW |

34 |

23 |

55 |

12.1 |

6.6 |

42 |

| 165/420-34W |

PW |

34 |

23 |

62 |

13.9 |

8.6 |

46 |

How to select the right filter mesh? You can follow these points

- Mesh size or the size of the particle you need to filter

- Mesh material (consider the working condition)

- Mesh thread diameter, Mesh thickness

- Opening area

Properties of Polymers

| Material |

PA6 |

PA66 |

PET |

PP |

PEEK |

| Specific gravity (g/mm²) |

1.14 |

1.14 |

1.38 |

0.91 |

1.30 |

| Tensile strength(daN/mm²) |

41-67 |

41-67 |

45-75 |

35-62 |

33-75 |

| Relative strength at wet conditions(%) |

89-90 |

85-90 |

100 |

100 |

100 |

| Elongation at break (%) |

20-35 |

20-35 |

15-30 |

20-50 |

20-40 |

| Moisture absorption at 20°C / 65% r.h. (%) |

3.5-4 |

3.5-4 |

0.4 |

0 |

0.1 |

| Melting point (°C) |

210-220 |

260-268 |

250-260 |

165-175 |

334 |

| Softening point (°C) |

- |

- |

220-240 |

140-155 |

300 |

| Working temperature dry (°C) |

- |

- |

-75 to +150 |

-30 to +90 |

up to 250 |

| Stability to light |

poor |

poor |

poor |

poor |

good |

| Atmospheric influence |

- |

- |

none |

none |

none |

| Abrasion resistance |

good |

good |

limited |

limited |

good |

| Acid resistance |

limited-poor |

limited-poor |

good |

good |

good |

| Alkaline resistance |

good |

good |

limited |

good |

good |

| Stability to solvents |

limited |

limited |

good |

good |

good |

| Hydrolysis resistance |

good |

good |

limited |

good |

good |

The Production Process of Filter Mesh

Share Filters Manufacture Capabilities

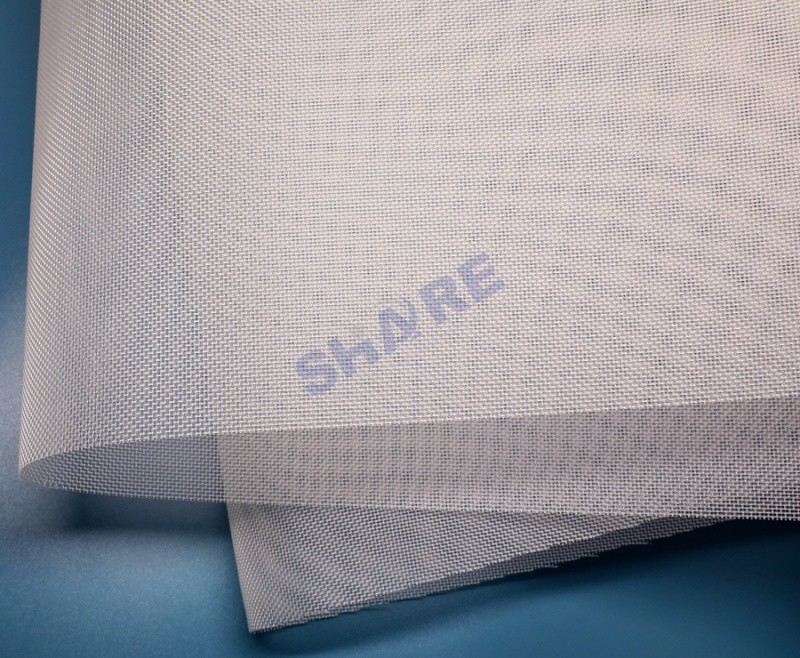

Share Filters in-house capabilities include enhanced processing such as filter mesh slitting, punching, tubing,

welding,sewing, dyeing, injection molding and finishing of products. Share Filters Can Offer the Nylon Filter

Mesh, Polyester mesh, PP filter mesh, metallic mesh in Different Types to meet customs' Filtration demands.

|

|

|

| Share Filter synthetic meshes can be made from a variety of materials such as polyamide, polyester, polypropylene, etc. You can order by the roll or in cutting shapes. |

Ultrasonic slitting is also used for manufacturing fabric strips and produces a closed edge with very little material build up at the edge. |

Our cutting method include Laser cutting, Cold cutting, Hot cutting, Slitting, Punching. Professional cutting using custom made tools that will not damage the materials. |

|

|

|

| Sonic welding are accurate, clean. precision, sleeves and bags for blood filtration, biopsy bag for rosin bag for rosin press are examples of applications that benefit from this technology. |

Share Filters sewing products are carried out by highly skilled and experienced machinists, which ensure you get the right level of consistent quality. |

Custom plastic molded filter combine precise filter mesh with polymer plastic. Industry serve: Automotive, Appliances, Food and beverage, Medical, Life Science and Laboratory, etc. |

About Us

Share Filters has over 20 years of experience developing and manufacturing filter mesh and custom product for our customer's screen and filtration needs. We can offer the filter mesh and filter components services including slitting, cutting, welding, sewing and injection molding. Our customer base comes from a wide variety of industries including – Automotive, Home appliances, Food and beverage, Milling, Medical, Life Science and laboratory, Electronical as well as more general engineering, giving us a wealth of experience in many areas.

Industries We Serve

|

|

|

|

|

|

| Automotive |

Appliance |

Medical |

Food & Beverage |

Chemical |

Environmental |

Custom Made Products

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!