Product Description

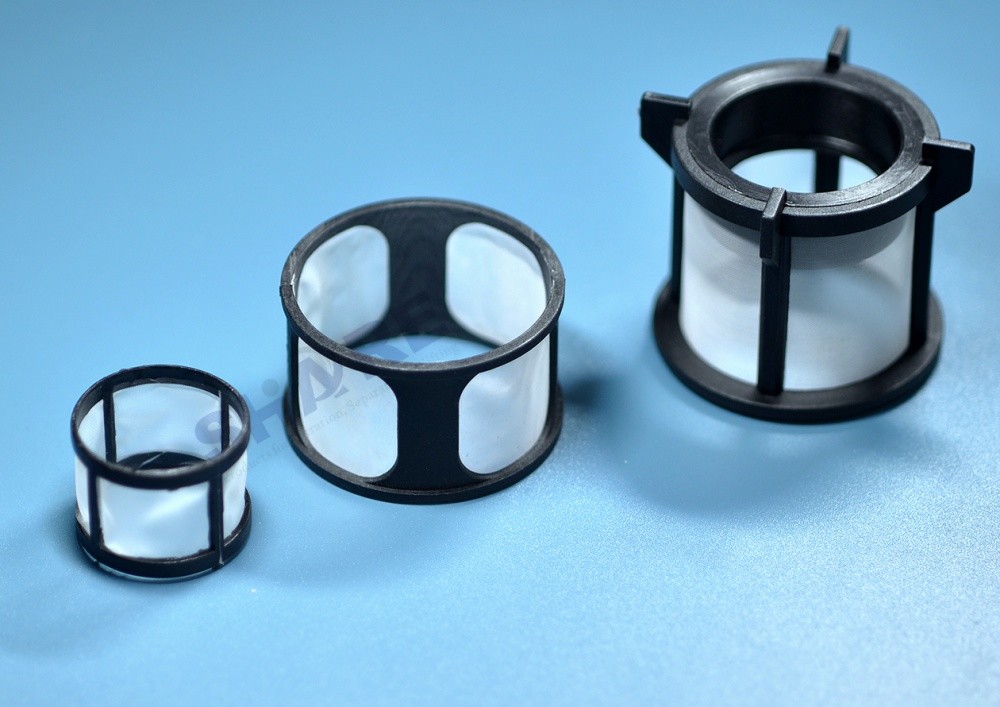

High Performance Truck Fuel Pump Filter Custom-Made Inline Diesel Strainer

A truck fuel filter is a component of a truck's fuel system that is designed to remove impurities and contaminants from the fuel before it reaches the engine. The primary function of a fuel filter is to protect the engine from harmful particles and debris that can cause damage or decrease performance. Fuel filters are typically located in the fuel line between the fuel tank and the engine, and they come in various shapes and sizes depending on the specific make and model of the truck.

There are two main types of fuel filters: inline filters and cartridge filters. Inline filters are typically located in the fuel line, this types of filters work by trapping contaminants and preventing them from entering the engine.

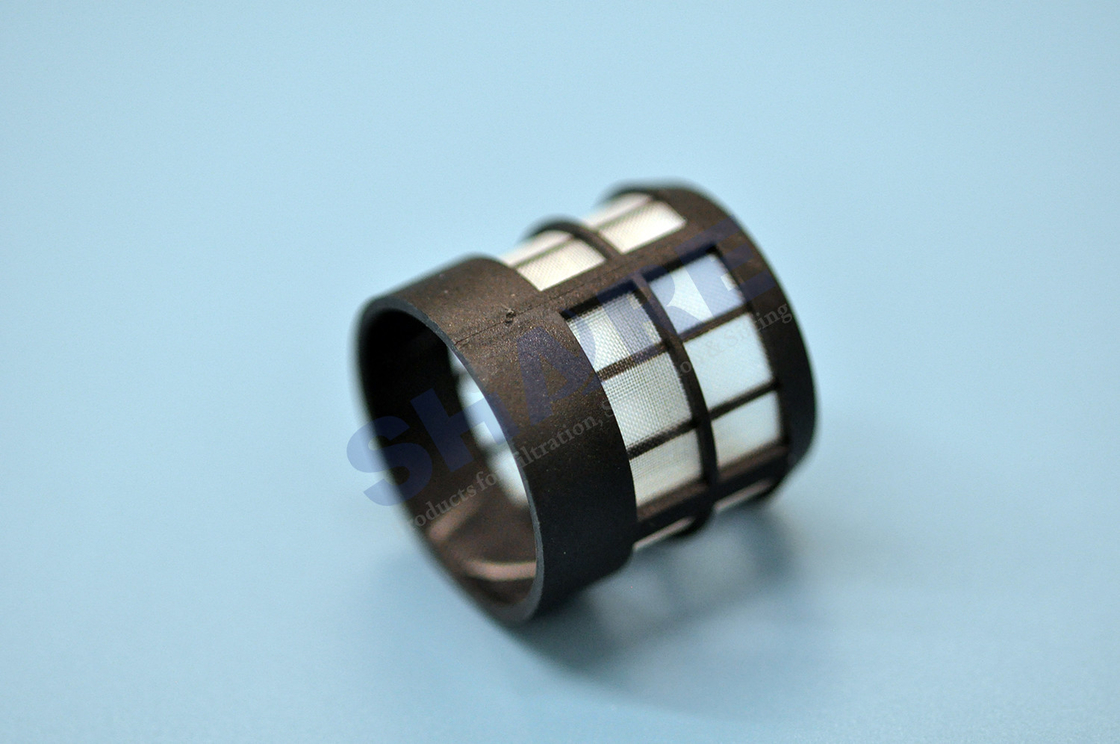

Share Filters' inline fuel filter is made by mesh insert injection moulding, it consist of a filter mesh held in a polymer plastic frame, allowing for a more robust part/product giving more reliability and longevity in its use. Injection moulding can take many forms and Share Filters is fully capable to help develop and produce the injection moulded filter product that will best suit your needs, as well as, offering any additional advice or service along the way.

Plastic Injection Molded Filters Materials Options

| Support frame material |

PA6, PA66, PET, PP, ABS, and other High-Performance Thermoplastics |

| Filter media |

Nylon mesh, polyester mesh, PP mesh, metallic mesh |

| Micron rating |

16μm - 1500μm |

| Mesh parts fabrication |

Laser cutting, sonic welding |

| Process |

Injection moulding |

| Specification |

Custom |

| Colour |

Custom |

Plastic Material Selection

When selecting the plastic, it is important to take into account the specific requirements of the plastic part. At our facility, we have the capability to work with a wide range of commonly used polymers, including PE, PP, ABS, PC, POM, PBT, PA, PPA, PPS, and even high-performance materials like PEEK. This allows us to provide tailored solutions that meet the unique needs of our customers.

Properties of Plastic

| Material |

PA6 |

PA66 |

PET |

PP |

PEEK |

| Specific gravity (g/mm²) |

1.14 |

1.14 |

1.38 |

0.91 |

1.30 |

| Tensile strength(daN/mm²) |

41-67 |

41-67 |

45-75 |

35-62 |

33-75 |

| Relative strength at wet conditions(%) |

89-90 |

85-90 |

100 |

100 |

100 |

| Elongation at break (%) |

20-35 |

20-35 |

15-30 |

20-50 |

20-40 |

| Moisture absorption at 20°C / 65% r.h. (%) |

3.5-4 |

3.5-4 |

0.4 |

0 |

0.1 |

| Melting point (°C) |

210-220 |

260-268 |

250-260 |

165-175 |

334 |

| Softening point (°C) |

- |

- |

220-240 |

140-155 |

300 |

| Working temperature dry (°C) |

- |

- |

-75 to +150 |

-30 to +90 |

up to 250 |

| Stability to light |

poor |

poor |

poor |

poor |

good |

| Atmospheric influence |

- |

- |

none |

none |

none |

| Abrasion resistance |

good |

good |

limited |

limited |

good |

| Acid resistance |

limited-poor |

limited-poor |

good |

good |

good |

| Alkaline resistance |

good |

good |

limited |

good |

good |

| Stability to solvents |

limited |

limited |

good |

good |

good |

| Hydrolysis resistance |

good |

good |

limited |

good |

good |

How to select the right filter mesh? You can follow these points.

- Mesh size or the size of the particle you need to filter

- Mesh material (consider the working condition)

- Mesh thread diameter, Mesh thickness

- Opening area

Application of Share Molded Filters

|

|

|

|

|

| Automotive |

Irrigation |

Food |

Appliance |

Health care |

About Share Filters

Share Filter's team is committed to providing comprehensive assistance for your filtration needs. Our team is equipped to assist you at every stage of the development process, from the initial idea to the final delivery of your project. Our skilled engineers specialize in creating mesh inserts for industrial filters and can create prototype designs tailored to your specific requirements. We can customize the size of the mesh filter openings to suit a wide range of applications. Mesh insert injection-molded plastic filters are ideal for numerous industries: Appliance, Automotive, Medical, Electronics, Industrial, Agricultural, environment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!