High Temperature Resistance and Chemical Resistance Polyphenylene Sulfide PPS Mesh

Material

100% PPS Monofilament

Forms

Fabric, Bag, Custom Shape

Performance

High Performance Material

Established in 1983, Taizhou Share Filters Co. Ltd. has specialized in producing standard precision mesh fabrics in various materials including polyamide, polyester, polypropylene, polyethylene, and stainless steel. We also develop high-performance materials like Polyphenylene Sulfide (PPS), Polyarylate (PAR), Polyetheretherketone (PEEK), ETFE, and Tungsten.

After years of research and development, SHARE has developed PPS Mesh, a unique material in China until 2020. PPS mesh represents a new generation of high-tech mesh materials specifically designed for applications requiring high resistance against temperature and chemicals.

Specifications

| Item Name | High Temperature Resistance And Chemical Resistance Polyphenylene Sulfide PPS Mesh |

| Manufacturer | Taizhou Share Filters Co. Ltd. |

| Brand | SHARE FILTERS |

| Material | Polyphenylene Sulfide (PPS) |

| Color | Slightly Yellow |

| Weave type | Plain woven, twill woven |

| Common width | 100cm, 127cm, 150cm, 160cm, 175cm, 200cm, 300cm or customized |

| Roll length | 30-100 meters or customized |

| Mesh Count/inch | 25 mesh/inch-420 mesh/inch |

| Thread diameter | 30um to 250um |

| Mesh Opening | 30um to 800um |

| Thickness | 56um to 508um |

| Certificate | ISO19001 SGS ROHS REACH |

Key Features

- High temperature resistance: 190°C in continuous operation

- Excellent hydrolysis and electrolysis resistance

- Superior alkali/acid and solvent resistance

- Excellent mechanical resistance

- Good flame resistance

- Minimal strength loss

- Highest fineness

- Recyclable

- Alternative for PEEK

Quality Control

Our production process includes visual inspection, optical or pressure sensitive equipment, and automated 3D image-inspection equipment to ensure consistent quality.

Applications

- Ion exchange processes

- Alkaline water electrolysis for hydrogen production

- Feed and food drying

- Filtration for food, semiconductor and chemical applications

- Chemical catalyst substrates

- Oil-water separation

- Gas filtration and purification

- Wastewater treatment

- Air pollution control

- Desalination

Product Options

PPS mesh specifications are designed to cater to diverse applications with the following customizable options:

- Thread Diameter: 30 - 250 µm

- Mesh Count: 25 - 420 per inch

- Mesh Opening: 30 - 800 µm

- Open Area: 25 - 60%

- Mesh Thickness: 56 - 508 µm

- Pattern: Plain weave, twill weave

- Width: Up to 300cm (customizable)

Technical Datasheet

| Material | Item No. | Specification | Thread Diameter (μm) | Mesh Opening (μm) | Open Area (%) | Mesh Thickness (μm) | Weight (g/m²) | Tensile Breaking Strength (N/5CM) | Tensile Elongation (%) |

| PPS | 20T-140 | 350/51PW | 140 | 350 | 51 | 260 | 86 | 660/643 | 29.5/27.8 |

| PPS | 20T-150 | 340/48PW | 150 | 340 | 48 | 280 | 100 | 766/755 | 29.5/28.4 |

| PPS (Toray yarn) | 20T-150 | 340/48PW | 150 | 340 | 48 | 287 | 100 | 810/780 | 24/24 |

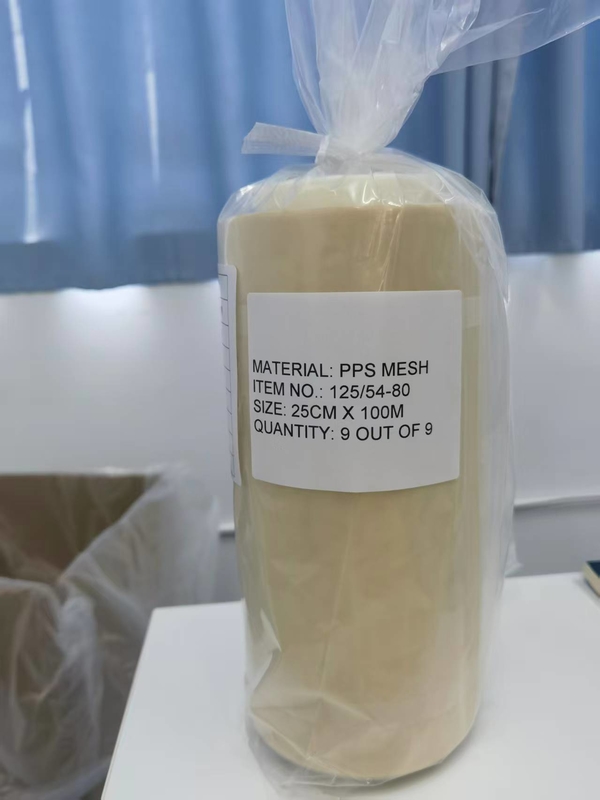

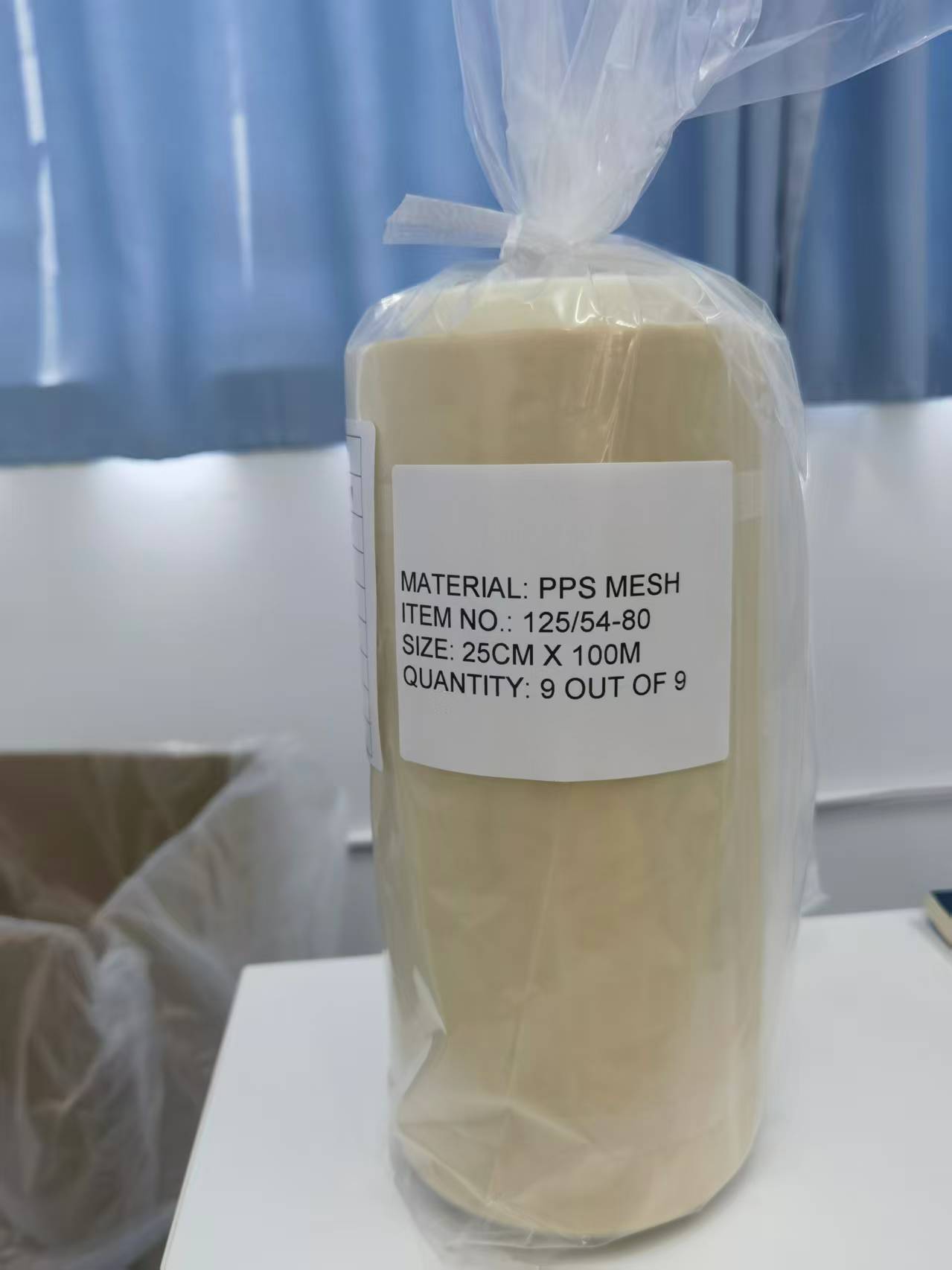

Product Images

Packaging & Shipping

Our standard packaging includes:

- Rolled on paper core or plastic pipe, packed into PE bags

- Placed in standard export carton

- Additional PP woven bag for transportation protection

Labels include: item name, manufacturer, material, dimensions, manufacturing date, order number, and batch number.

| Shipping Method | Port to Port | Door to Door |

| Express (DHL, UPS, FEDEX, EMS) | | 1 - 5 days |

| Air Freight | 1 - 5 days | 4 - 10 days |

| Sea Freight (FCL) | 15 - 30 days | 20 - 35 days |

| Sea Freight (LCL) | 15 - 30 days | 22 - 37 days |

Frequently Asked Questions

1. Where is your factory located? How can I visit there?

We are located in Taizhou city, Zhejiang province, China. Our facility is one hour by train from Hangzhou and two hours from Shanghai.

2. Can I get free samples and how long can you deliver them?

We provide free samples for evaluation, typically delivered within 2 days.

3. How long does a quotation take?

We usually respond within 2 days. If any details in your RFQ require confirmation, we will notify you promptly.

4. How quickly can I get my order finished?

Production lead time depends on quantity, typically taking 5 to 15 working days after order placement.

5. What about your quality control?

Our quality control includes operator self-inspections at every production stage, spot inspections, and final inspections by our QC team using visual inspection, optical equipment, and automated 3D image-inspection systems.

6. What's your largest advantage?

Our core competency lies in our comprehensive converting capabilities from yarn to finished products, backed by over 30 years of technical expertise and quality management.

7. What kind of payment terms do you accept?

We accept T/T, LC, and other standard payment methods.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!