Polyester Mesh Woven Filters for Straining, Sieving and Filtering

SHARE polyester mesh filters offer excellent dimensional stability, precise mesh openings, smooth surface, and superior tear resistance. These filters feature high tensile strength, good air permeability, chemical resistance, and temperature resistance, making them ideal for various industrial applications.

Key Applications

Air Venting

Used in HVAC systems, industrial ventilation, and cleanroom environments to capture airborne particles and maintain air quality.

Tank Venting

Prevents contaminant entry while allowing gas exchange during tank filling and emptying processes.

Business Machines & Appliances

Improves air quality within electronic equipment by preventing dust and debris from entering sensitive components.

Automotive Equipment

Used for cabin air filtration, intake air filtration, and venting systems to maintain clean air within vehicles.

Pulp & Paper Production

Applied in air filtration, wastewater treatment, and production processes within the pulp and paper industry.

Food Processing

Removes particles and impurities from air or liquids in food production and packaging processes.

Cosmetic Processing

Maintains clean environments in cosmetic manufacturing facilities to ensure product quality.

Product Specifications

| Item Name |

Polyester Mesh Woven Filters for Industries |

| Manufacturer |

Taizhou Share Filters Co. Ltd. |

| Brand |

SHARE FILTERS |

| Material |

100% polyester monofilament mesh |

| Color |

Natural white |

| Weave type |

Plain woven, twill woven, dutch woven |

| Mesh opening |

15um to 4400um |

| Open area |

10% to 92% |

| Thickness |

40um to 1170um |

| Common width |

1cm to 390cm (Common roll widths: 50cm, 100cm, 127cm, 150cm, 160cm, 175cm, 183cm, 365cm) |

| Roll length |

30-100 meters or customized |

| Product type |

Filter mesh, filter cloth, mine sieving mesh, filter elements, filter disc, filter cylinder |

Key Features

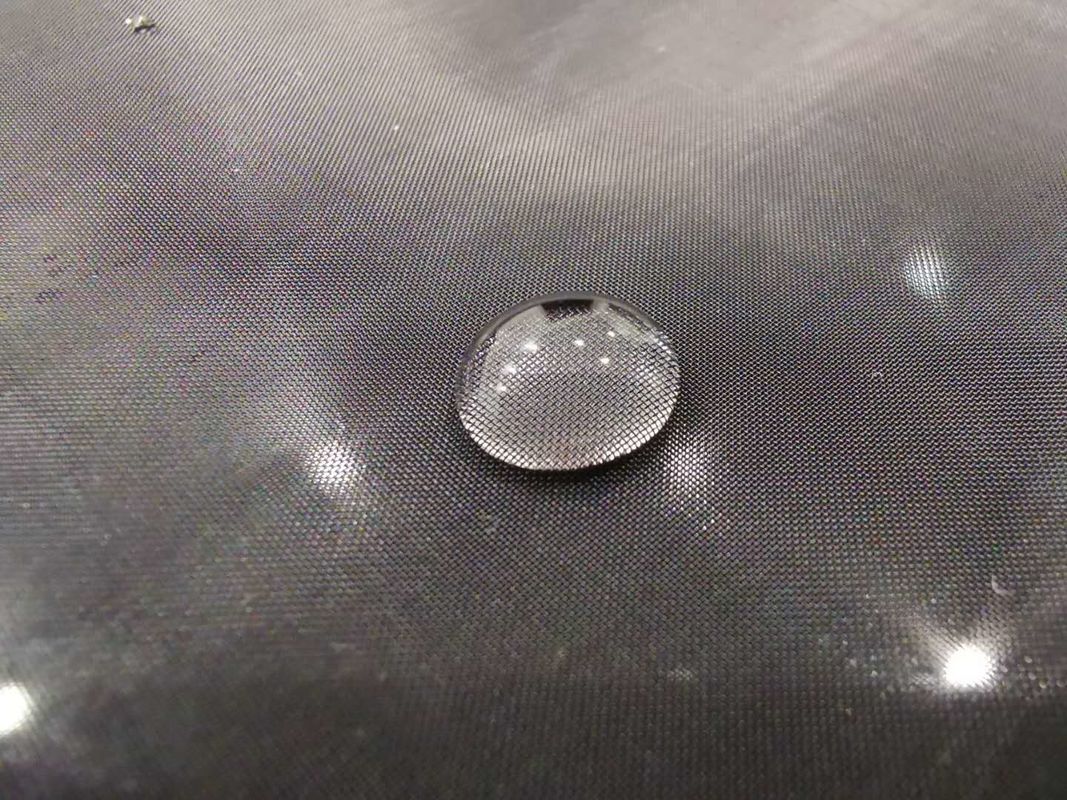

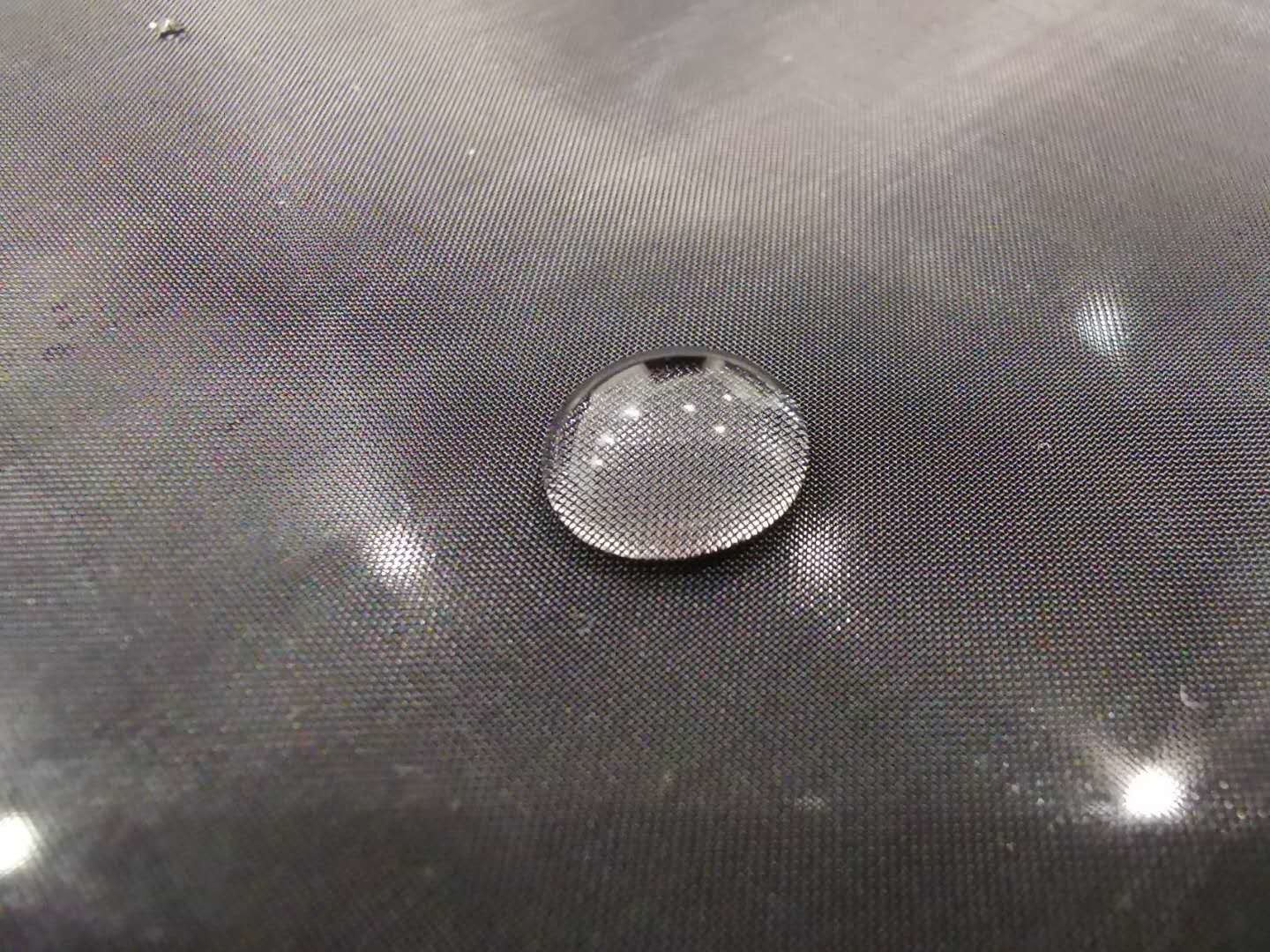

- Great dimensional stability with accurate and even mesh openings

- Smooth surface with excellent tear resistance and high tensile strength

- Good air permeability and high chemical resistance

- Excellent acid and solvent resistance with temperature resistance

- Low moisture absorbency

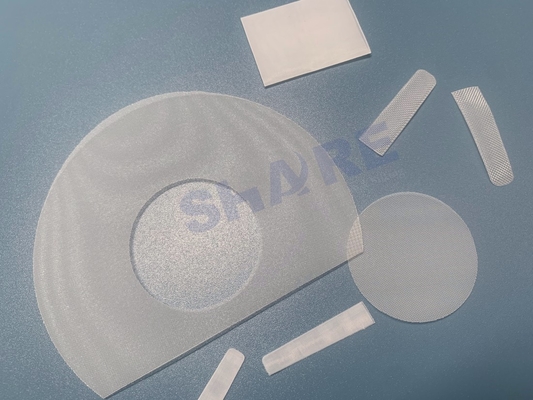

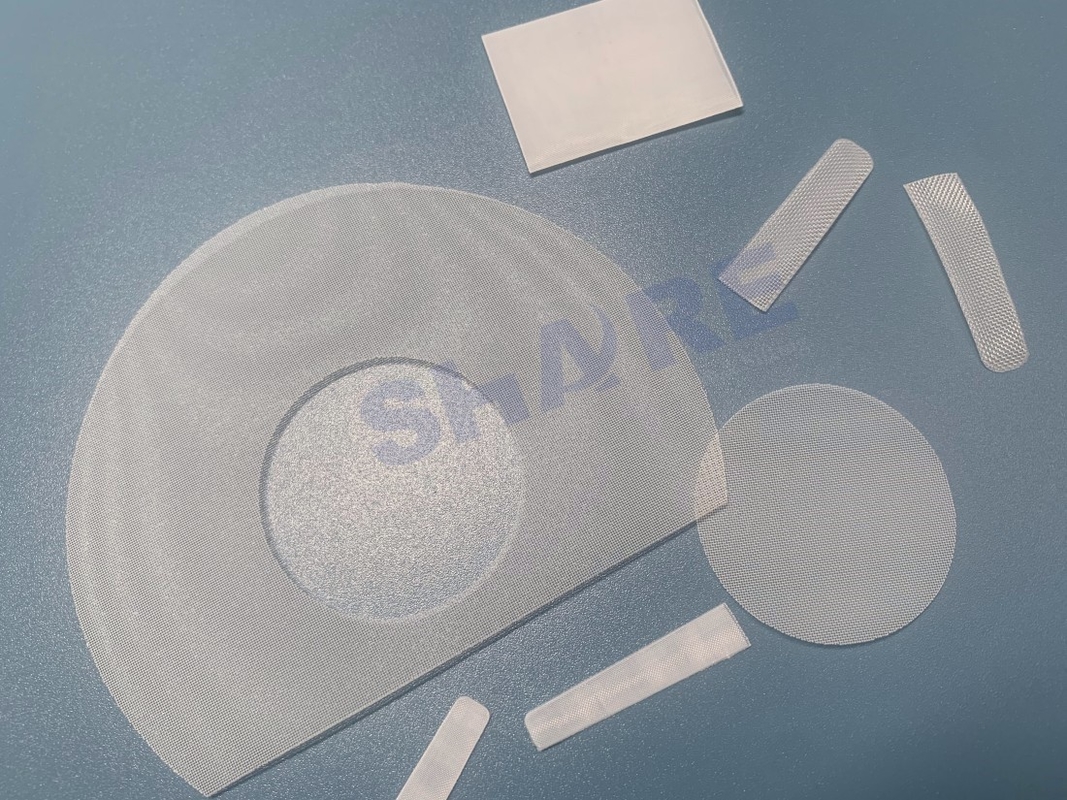

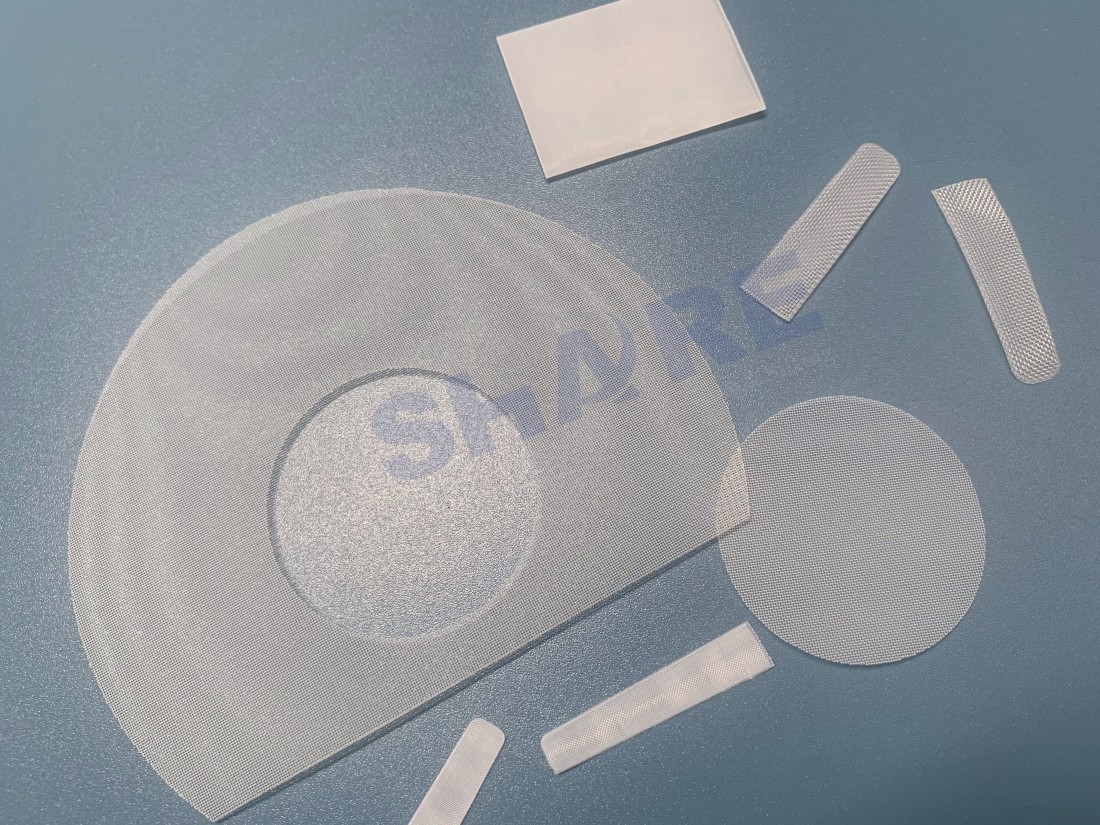

- Available in various shapes: roll, disc, ribbon, tube, bag, pleated components

- Compliance with food grade standards

- RoHS and REACH certified

Product Gallery

Technical Datasheet

SHARE Precision Polyester Filter Mesh Technical Data Sheet

| Fabric number |

Mesh count |

Thread diameter |

Mesh opening |

Open area |

Fabric thickness |

Weight |

| PES 4400/77.5 |

2T |

600 |

4400 |

77.5 |

1170 |

156 |

The data are compiled to the best of our knowledge. Subject to change without notice. Complete product range is available on request.

Production Process

Yarn

Monofilament with excellent diameter control for precise openings, high flow rates, and low pressure drops. Features easy-to-clean surface with high stiffness.

Weave

Plain weave construction creates durable fabrics with many crossing points for structural integrity and friction resistance.

Product Procedure

Yarn → Raw yarn inspection → Warping arranging → Drawing in heddle → Drawing in reed → Weaving → Initial survey → Washing → Heat setting treatment → Physical properties inspection → Products inspection → Fabricated mesh if needed → Plastic molded filters if needed

Company Profile

Established in 1983, Taizhou Share Filters Co., Ltd. specializes in woven monofilament filter mesh fabrics with micron ratings from 3um to 4mm. We engineer woven fabrics into finished or partly finished products.

Product Categories

|

Monofilament Mesh Rolls

- 30 years of experience & capabilities

- PA, PET, PP, PE, PPS, PEEK materials

- Precise mesh opening, open area and thickness

|

|

|

Discs, Tubes, Ribbons, Bags

- Cutting, calendering, welding, slitting, sewing

- Various converting capabilities

- Clean, smooth & closed edge quality

|

|

|

Plastic Molded Filters

- Insert molding and over molding

- High efficiency with low pressure drop

- High stability and reliability

|

|

Packaging & Shipping

For mesh rolls:

- Rolled on paper core (30-70m/roll) in PE bags with product labels

- 2-8 rolls per standard export carton

- PP woven bag outer protection

- Package belt reinforcement

For fabricated & molded filters:

- Sealed PE bags (10-500pcs/bag) with product labels

- Standard export carton packaging

- PE stretch film outer protection

- Package belt reinforcement for palletized shipments

Shipping Options

| Method |

Port to Port |

Door to Door |

| Express (DHL, UPS, FEDEX, EMS) |

1-5 days |

|

| Air Freight |

1-5 days |

4-10 days |

| Sea Freight (FCL) |

15-30 days |

20-35 days |

| Sea Freight (LCL) |

15-30 days |

22-37 days |

Frequently Asked Questions

1. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are one hour away from Hangzhou and two hours away from Shanghai.

2. Can I get free samples and how long can you deliver them?

We provide free samples for evaluation, which will be sent within 2 days.

3. How long does a quotation take?

We typically respond within 2 days. If additional confirmation is needed, we will promptly notify you.

4. How quickly can I get my order finished?

Production lead time depends on quantity, typically taking 5 to 15 working days after order placement.

5. What about your quality control?

Our operators conduct self-inspections at every stage, supplemented by spot inspections and final QC checks using optical equipment and automated 3D image-inspection systems.

6. What's your largest advantage?

Our core competency is excellent converting capabilities from yarn to finished products, backed by 30+ years of technical expertise and quality management.

7. What kind of payment terms do you accept?

We accept T/T, LC, and other standard payment methods.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!