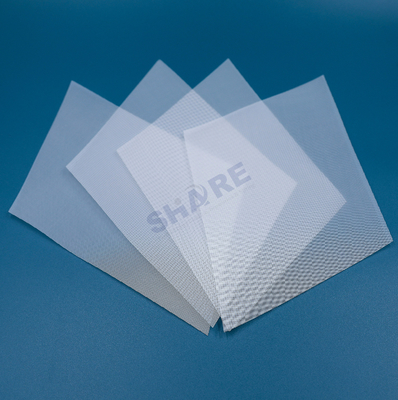

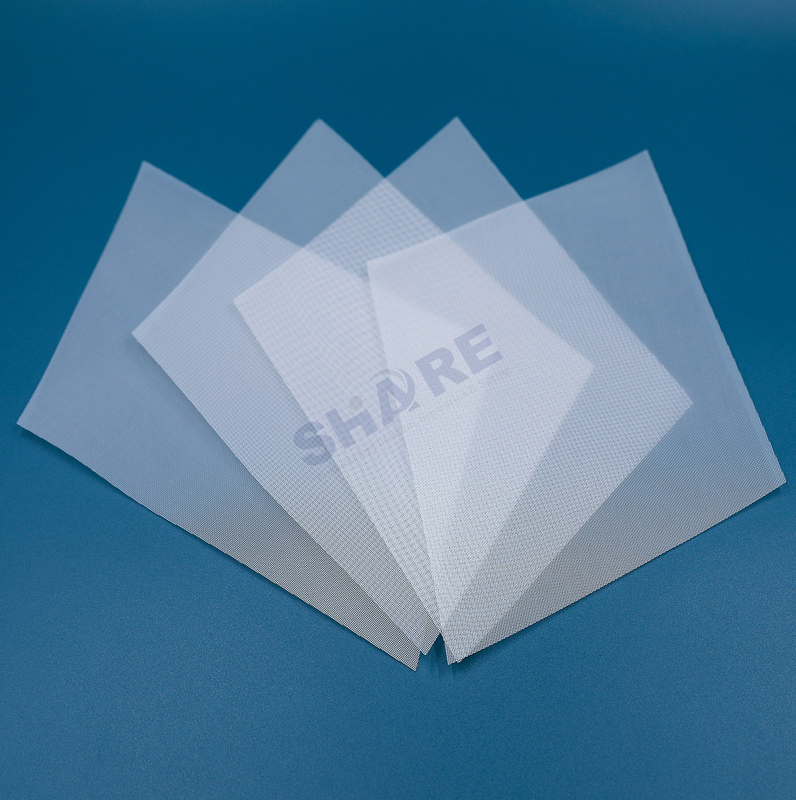

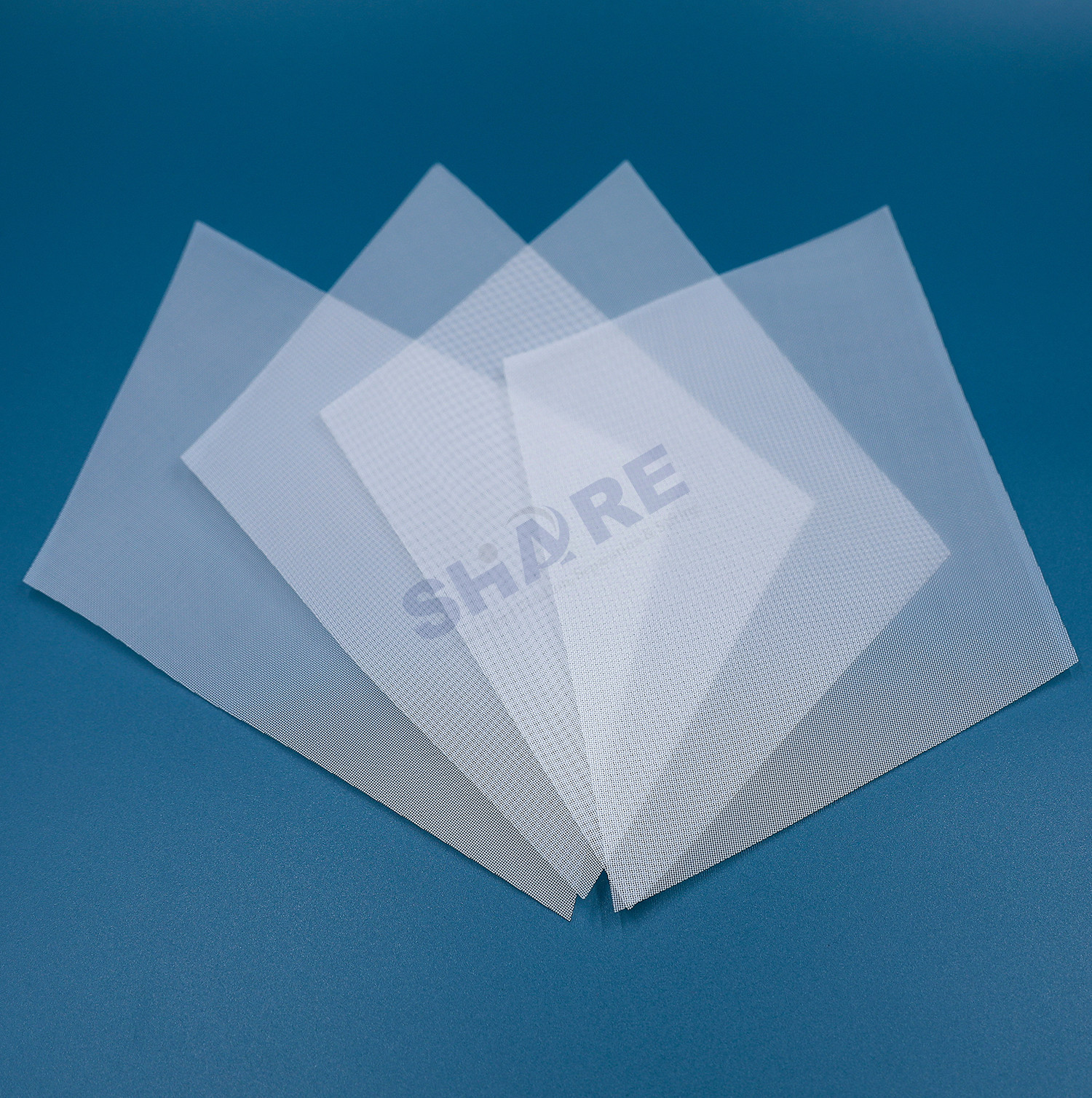

Product Description

SHARE has been customizing mesh components to fit our customers' needs and applications for decades. We are able to convert filter mesh fabrics into various specific pieces and shapes such as discs, tubes, ribbons, shapes, cut-to-size sections, bags. These are just a few examples that SHARE processes with ultrasonics technology.

To ensure precision, speed and the ultimate product quality, SHARE has made significant investments in its state-of-the-art ultrasonics cutting operations.

At SHARE, We have in house developed custom ultrasonics cutting&stamping machines. As a result, you can rely on high precision, outstanding cutting, closed sealed edges, and the consistent quality required by SHARE's world - class mesh filters - every time.

The main advantages of SHARE ultrasonics cutting of mesh filter pieces and shapes:

1. High precision and repeatability

In house developed ultrasonics machines with ultra fine mold ensure the cut pieces are precise and consistent. Normally the cutting quality of ultrasonics is much better compared to the laser.

2. Clean, closed cut edges

Woven fabrics can easily fray after cutting, but the heat generated by the ultrasonics creates sealed edges due to melting.

3. High cutting speed

High speed ultrasonics machines combined with SHARE custom designed roll-off mechanism to process filter material from rolls instead of sheets. This results in significant faster production times. Thus we guarantee fast delivery for normal orders.

Specifications

| Item name |

Ultrasonics cut PP screen mesh filter pieces |

| Manufacturer |

Taizhou Share Filters Co. Ltd. |

| Brand |

SHARE FILTERS |

| Material |

100% polypropylene monofilament yarn, other materials such as PA PET PE are available. |

| Color |

White or other colors |

| Fabrication shape |

Round, square, rectangular, trapezoidal, circular, etc.

It can be customized according to your request or drawings |

| Mesh opening |

15-3000 microns for your option. |

| Product process |

Ultrasonics cut |

| Sample |

Available |

| Features |

Custom shapes

Suited for healthcare applications

Traceability

Non-fraying sealed edges |

| Certificate |

ISO19001 SGS ROHS REACH |

| Application |

Liquid filtration, medical filtration, and semi finished fabricated mesh filters are particularly suitable for use in injection molding processes |

Product Gallery

Customers have different requirements for filtration & separation, and relying only on ultrasonics cutting technology is not sufficient to meet the challenges of today's demanding filtration market. Therefore, after years of developments, SHARE has developed expertise in almost all processing technologies, including cold cut&stamping, heat slitting, laser cutting, ultrasonics cutting, sewing, pleating, and injection molding etc.

Filter piece and shapes are essential for insert molding. We are happy to advise the best fabrication technology to customers application and requirement.

Here are some examples of our fabricated polypropylene(pp) mesh filters:

Laser&ultrasonics cut polypropylene single or multiple layer irregular shapes

Laser cut and ultrasonics cut polypropylene tubes, ready for insert molding

Polypropylene strip ring, cut by laser and then welded by ultrasonics

Polypropylene cylindrical tube, mesh cut by laser and over-lapped welded to tube by ultrasonics

Polypropylene continuous tube

Polypropylene corner/edge welded tube cut

Polypropylene plastic ring welded liquid filter bag

Polypropylene welded bag for medical filtration

Injection molding polypropylene mesh filters

We have created thousands of filtration solutions to help customers achieve the best filtration configuration and solution for various applications, including appliance, electronics, medical and healthcare, automotive, food and beverage, mining, architecture, aerospace etc.

Please feel free to contact us for any filtration inquiry, and our application specialists will be glad to provide our best filtration solution for you.

Product Procedure

At Share, from yarn to product, every phase of production is carefully monitored, employing frequent in-house testing and rigorous inspection to ensure consistent quality at every step of production. Mesh thickness, open area, mesh count and air permeability are all subject to strict controls which result in high quality final products.

Each batch of our filter meshes undergoes a meticulous process involving at least twelve distinct steps, ensuring the ultimate production of high-quality filtering products. The steps of SHARE filter mesh production procedure are:

Yarn→Raw yarn inspection→Warping arranging→Drawing in heddle→Drawing in reed→Weaving→Initial survey→Washing→Heat setting treatment→Physical properties inspection→Products inspection→Product→Fabricated filter and screens if needed→Molded plastic filters if needed

Based on customer drawings or requirements, SHARE filter mesh can be further processed into various types of cut-to-size filter stamped discs, pieces, shapes, ribbons, tubes, bags, injection molded filter etc.

Technical Datasheet

| SHARE Precision Polypropylene Filter Mesh Technical Data Sheet |

| Fabric Number |

Mesh Count |

Thread Diameter |

Mesh Opening |

Open Area |

Fabric

Thickness |

Weight |

| No. |

mesh/cm |

um |

um |

% |

um |

g/m² |

| PP-3360/60 |

2.3 |

1000 |

3360 |

60 |

1800 |

340 |

| PP-2400/50 |

2.9 |

1000 |

2400 |

50 |

1730 |

470 |

| PP-2000/51 |

3.6 |

800 |

2000 |

51 |

1310 |

310 |

| PP-1680/46 |

4 |

800 |

1680 |

46 |

1600 |

410 |

| PP-1190/42 |

5.5 |

600 |

1190 |

42 |

1340 |

318 |

| PP-1000/45 |

6.8 |

500 |

1000 |

45 |

1020 |

300 |

| PP- 840/45 |

8 |

440 |

840 |

45 |

725 |

190 |

| PP- 710/41 |

9 |

440 |

710 |

41 |

800 |

216 |

| PP- 500/36 |

12.2 |

340 |

500 |

36 |

610 |

180 |

| PP- 420/30 |

13.9 |

300 |

420 |

30 |

610 |

200 |

| PP- 405/41 |

16.8 |

230 |

405 |

41 |

350 |

100 |

| PP- 350/32 |

16.2 |

270 |

350 |

32 |

515 |

160 |

| PP- 297/35 |

20 |

215 |

297 |

35 |

420 |

125 |

| PP- 295/23 |

16.2 |

340 |

295 |

23 |

610 |

245 |

| PP- 280/41 |

22.7 |

165 |

280 |

41 |

300 |

90 |

| PP- 250/29 |

22.2 |

215 |

250 |

31 |

430 |

140 |

| PP- 210/32 |

27 |

165 |

210 |

32 |

295 |

95 |

| PP- 177/29 |

29 |

165 |

177 |

29 |

314 |

110 |

| PP- 150/34 |

38.5 |

110 |

150 |

34 |

195 |

65 |

| PP- 125/30 |

43.5 |

106 |

125 |

30 |

200 |

68 |

| PP- 105/25 |

47.5 |

106 |

105 |

25 |

230 |

78 |

| PP- 105/16 |

36,5 |

165 |

105 |

16 |

360 |

134 |

| PP-3360/60 |

2.3 |

1000 |

3360 |

60 |

1800 |

340 |

| PP-2400/50 |

2.9 |

1000 |

2400 |

50 |

1730 |

470 |

| PP-2000/51 |

3.6 |

800 |

2000 |

51 |

1310 |

310 |

| PP-1680/46 |

4 |

800 |

1680 |

46 |

1600 |

410 |

| PP-1190/42 |

5.5 |

600 |

1190 |

42 |

1340 |

318 |

| PP-1000/45 |

6.8 |

500 |

1000 |

45 |

1020 |

300 |

| PP- 840/45 |

8 |

440 |

840 |

45 |

725 |

190 |

| PP- 710/41 |

9 |

440 |

710 |

41 |

800 |

216 |

| PP- 500/36 |

12.2 |

340 |

500 |

36 |

610 |

180 |

| PP- 420/30 |

13.9 |

300 |

420 |

30 |

610 |

200 |

| PP- 405/41 |

16.8 |

230 |

405 |

41 |

350 |

100 |

| PP- 350/32 |

16.2 |

270 |

350 |

32 |

515 |

160 |

| PP- 297/35 |

20 |

215 |

297 |

35 |

420 |

125 |

| PP- 295/23 |

16.2 |

340 |

295 |

23 |

610 |

245 |

| PP- 280/41 |

22.7 |

165 |

280 |

41 |

300 |

90 |

| PP- 250/29 |

22.2 |

215 |

250 |

31 |

430 |

140 |

| PP- 210/32 |

27 |

165 |

210 |

32 |

295 |

95 |

| PP- 177/29 |

29 |

165 |

177 |

29 |

314 |

110 |

| PP- 150/34 |

38.5 |

110 |

150 |

34 |

195 |

65 |

| PP- 125/30 |

43.5 |

106 |

125 |

30 |

200 |

68 |

| PP- 105/25 |

47.5 |

106 |

105 |

25 |

230 |

78 |

| PP- 105/16 |

36,5 |

165 |

105 |

16 |

360 |

134 |

The data are compiled to the best of our knowledge, NOT a complete product range. Complete product range is available on request.

Subject to change without notice.

What SHARE can do for you?

Whether you want to improve the quality or reduce the cost of your existing filter component, plan a new filtration application, or need assistance with specifications and design validation, SHARE is here for you. Our specialist problem solving skills are ready to address any challenges you encounter.

By vertical integration of our global supply chain and expertise, our extensive manufacturing and production facilities, our experiences of filtration team, as well as our materials management, we take end-to-end control of all the steps in the manufacturing process, including weaving, fabrication, molding. Our ability to efficiently manufacture products not only ensures repeatable product quality, but also maintains a steady supply chain, reduces production costs and shortens lead times for our customers.

We aim to offer the most reliable and cost effective filter solutions for all filtration applications. SHARE application speciallists with decades of experiences will help you select the best filter solution for your application.

Contact SHARE today for additional information and how we can help you with your specific filtration requirements.

Packaging & Shipping

For mesh rolls:

1. Rolled on the paper core, 30-70m/roll, packed into PE bags, the product label is attached on the edge of each roll

2. 2-8 rolls per standard export carton

3. Put into PP woven bag to prevent damage during transportation

4. Package belt strengthen

For fabricated & molded filters:

1. Packed into sealed PE bags, 10pcs to 500pcs/bag according to the actual size, double bagged and the product label is attached in the inner bag

2. Put into bigger PE bag and then standard export carton

3. Wrapped the outer carton with PE stretch film to prevent damage during transportation

4. Package belt strengthen if pallets are available

The label contains the following standard information:

item name, manufacturer, material, dimensions, manufacturing date, order number, batch number etc.

| |

Port to Port |

Door to Door |

| Express(DHL,UPS,FEDEX, EMS) |

|

1 - 5 days |

| Air Freight |

1 - 5 days |

4 - 10 days |

| Sea Freight(FCL) |

15 - 30 days |

20 - 35 days |

| Sea Freight(LCL) |

15 - 30 days |

22 - 37 days |

FAQ

1. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are one hour away from Hangzhou and two hours away from Shanghai.

2. Can I get free samples and how long can you deliver them?

We are pleased to provide you with free samples for your evaluation, which will be sent to you within 2 days. Please feel free to reach out to us for samples.

3. How long does a quotation take?

In most cases, we respond within 2 days. If something in RFQ need be confirmed, we will promptly notify you soon.

4. How quickly can I get my order finished?

The production lead time is dependent on the quantity. Typically, it takes 5 to 15 working days for us to complete mass production once you have placed the order.

5. What about your quality control?

By visual inspection, optical or pressure sensitive equipment and automated 3D image-inspection equipment, our production operators conduct self-inspections at every stage of the process. Additionally, we have spot inspections and final inspections carried out by our Quality Control (QC) team.

6. What's your largest advantage?

One of our core competencies is our excellent converting capabilities from yarn over weaving to converted items with professional technical team and quality guarantee and management for more than 30 years.

7. What kind of payment terms do you accept?

T/T and LC and more.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!