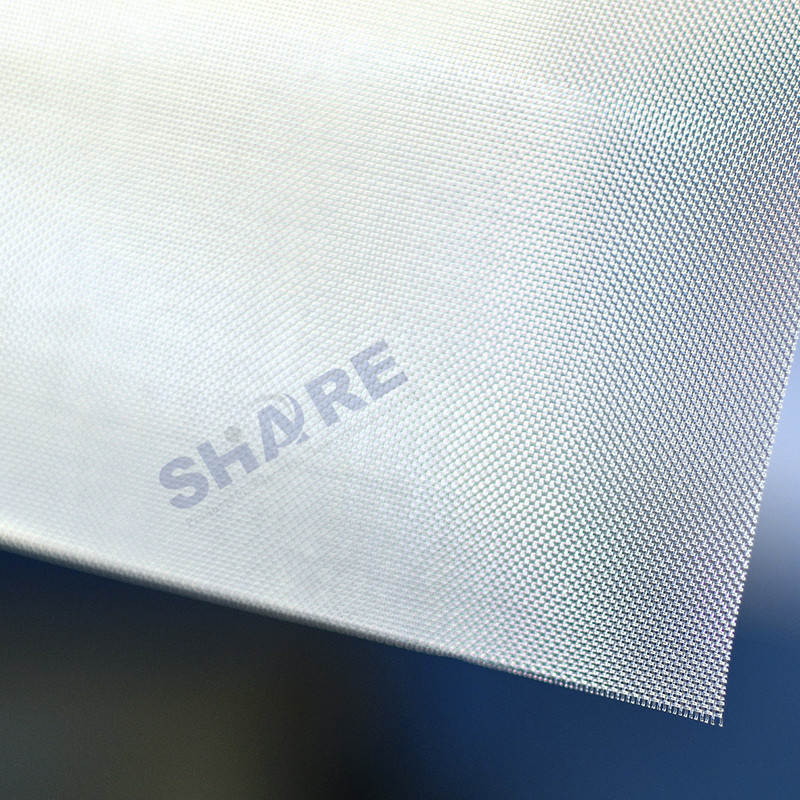

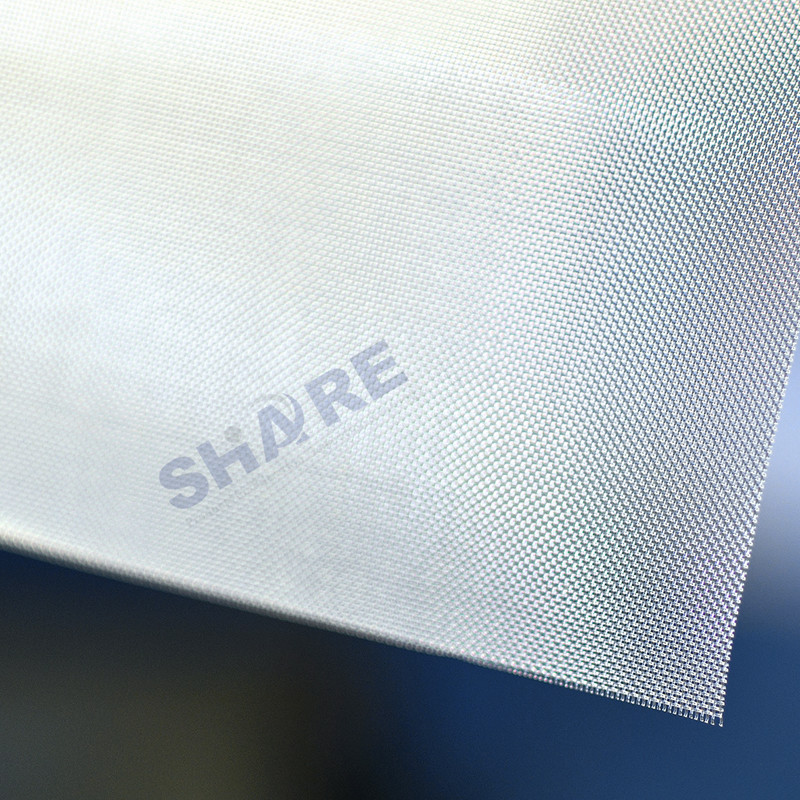

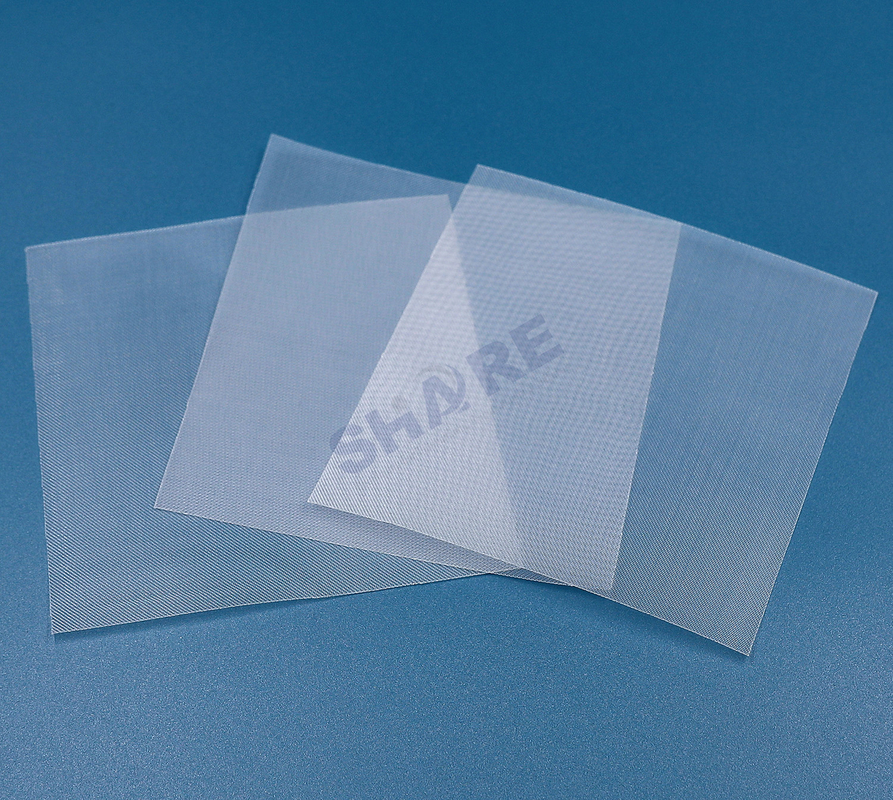

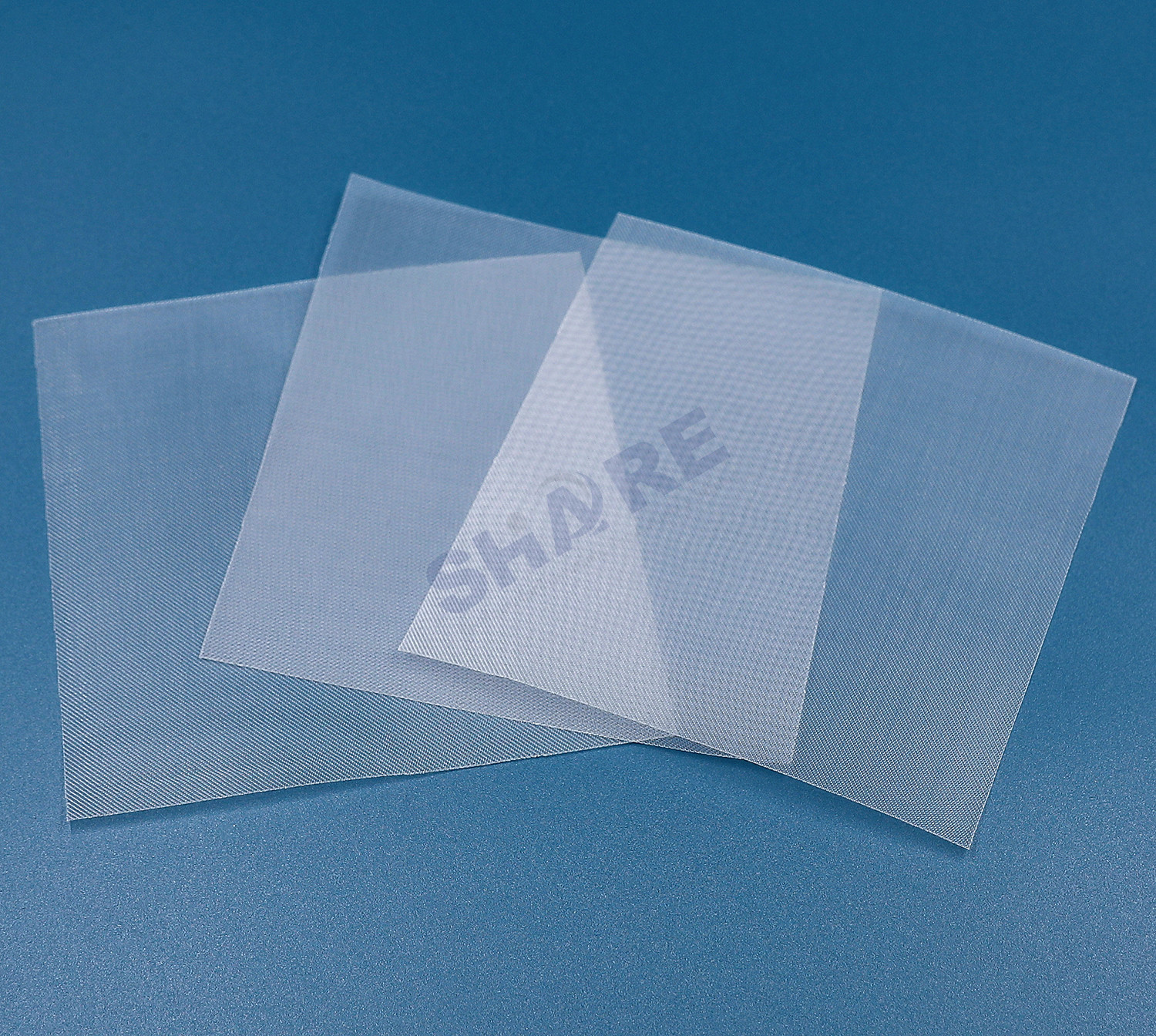

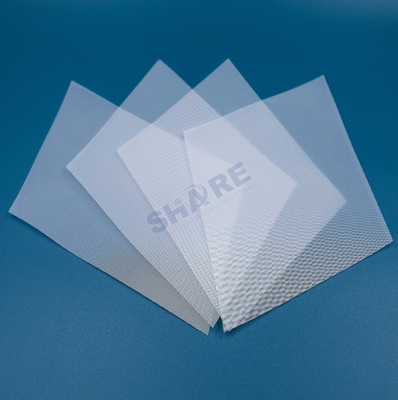

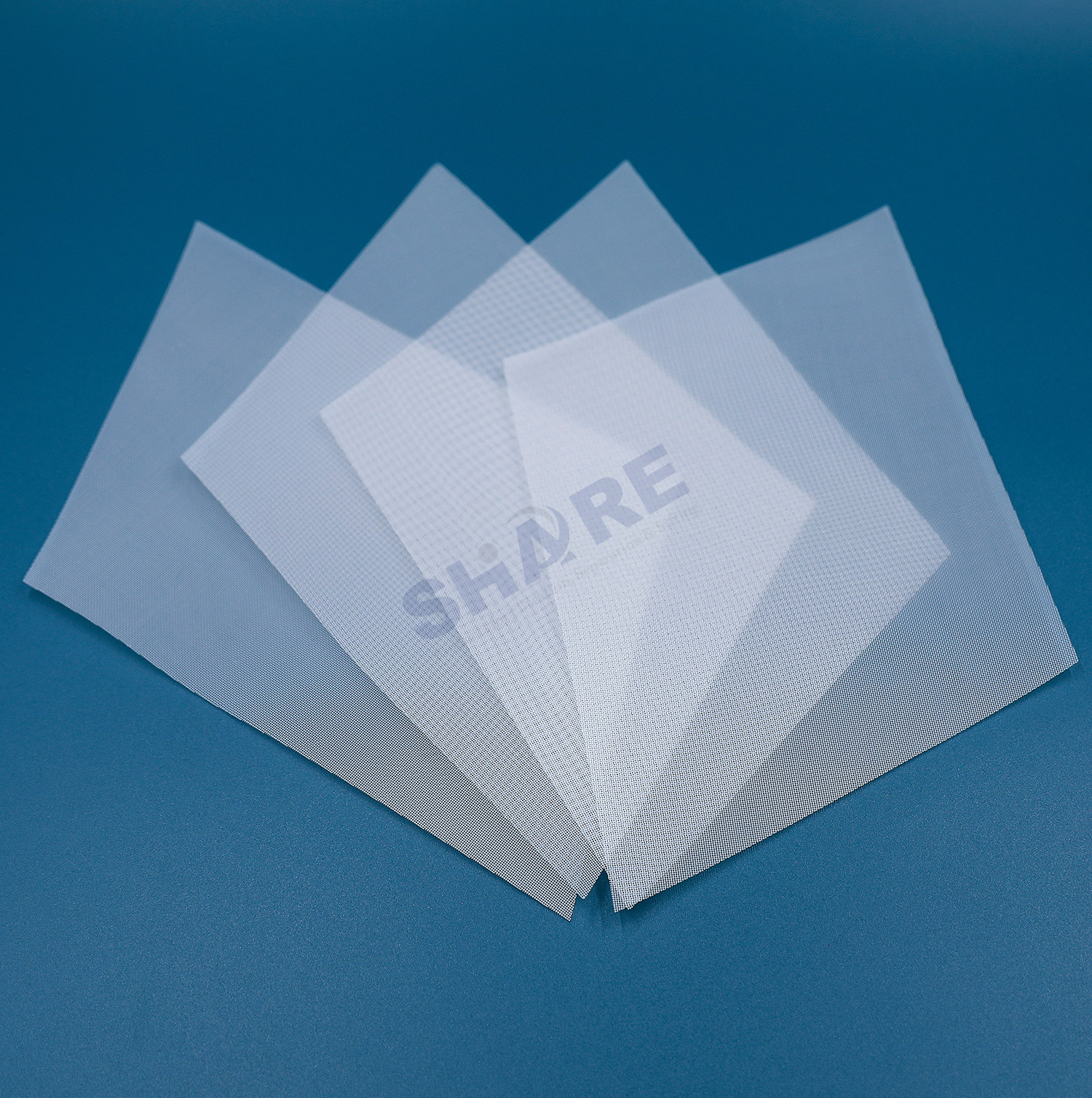

Polypropylene (PP) Woven Mesh Filters

SHARE polypropylene (PP) mesh filters offer high weldability, excellent hydrolysis resistance, and superior chemical resistance to biological, alkali, mineral acids, organic acids and oxidizing agents, with no moisture absorbency.

Key Applications

- Photoresist/Semiconductor Manufacturing: Removes particulates and impurities from chemicals to ensure purity of photoresist materials.

- Electronic Fluid Filtration: Traps particles in cooling systems or hydraulic circuits to protect sensitive electronic components.

- Air Venting: Captures airborne particles in HVAC systems, industrial ventilation, and cleanroom environments.

- Tank Venting: Prevents contaminant entry while allowing gas exchange during tank filling/emptying.

- Pulp & Paper Production: Removes impurities from water or chemical solutions to improve paper quality.

- Cosmetic Processing: Ensures ingredient purity and prevents unwanted particles in cosmetic products.

Specifications

| Item Name | Polypropylene (PP) Woven Mesh Filters for Photoresist/Semi-Conductor, Electronic Fluid Filtration, Air/Tank Venting |

| Manufacturer | Taizhou Share Filters Co., Ltd. |

| Brand | SHARE FILTERS |

| Material | 100% PP monofilament mesh |

| Color | Natural white |

| Weave type | Plain woven, twill woven, dutch woven |

| Mesh opening | 10-3360 microns (professional advice available) |

| Open area | 1% to 67% |

| Thickness | 50um to 1900um |

| Roll width | 1cm to 390cm (standard widths available) |

| Roll length | 30-100 meters or customized |

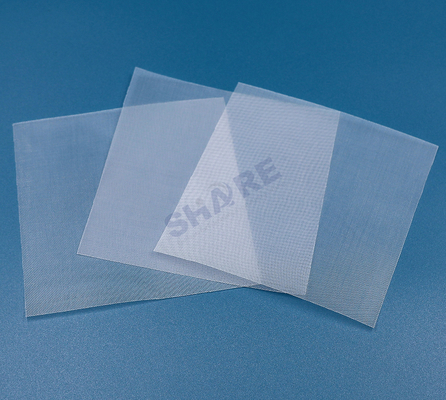

| Product type | Roll, disc, ribbon, shapes, bag, pleated components in various forms |

| Processing technologies | Colored, coated, thermal treated, sectioned, shaped, pleated, sewed or molded |

| Quality control | Visual inspection, optical/pressure sensitive equipment, automated 3D image-inspection |

| Certificate | ISO19001 SGS ROHS REACH |

Gallery

Technical Datasheet

| Fabric Number | Mesh Count | Thread Diameter | Mesh Opening | Open Area | Fabric Thickness | Weight |

| PP-3360/60 | 2.3 | 1000 | 3360 | 60 | 1800 | 340 |

The data are compiled to the best of our knowledge. Subject to change without notice.

Production Process

Our precision manufacturing process ensures consistent quality and performance:

- Yarn: Monofilament with excellent diameter control for precise openings

- Weaving: Plain, twill or dutch weave options for different requirements

- Quality Control: Multiple inspection points throughout production

Company Profile

Established in 1983, Taizhou Share Filters Co., Ltd. specializes in woven monofilament filter mesh fabrics with micron ratings from 3um to 4mm.

Our Product Categories

| Monofilament Mesh Rolls | 30 years experience, precise mesh openings, excellent converting capabilities |

| Discs, Tubes, Ribbons, Bags | Custom cutting, welding, slitting, sewing with clean edge quality |

| Plastic Molded Filters | Insert/over molding with extensive material options and industry-best lead times |

Packaging & Shipping

Mesh Rolls:

- Rolled on paper core, 30-70m/roll in PE bags with product labels

- 2-8 rolls per export carton with PP woven outer bag

Fabricated & Molded Filters:

- Sealed PE bags (10-500pcs/bag) with double bagging

- Standard export carton with PE stretch film protection

Shipping Options:

| Method | Port to Port | Door to Door |

| Express (DHL, UPS, FEDEX, EMS) | 1-5 days | 1-5 days |

| Air Freight | 1-5 days | 4-10 days |

| Sea Freight (FCL) | 15-30 days | 20-35 days |

| Sea Freight (LCL) | 15-30 days | 22-37 days |

FAQ

1. Where is your factory located?

We are in Taizhou city, Zhejiang province China, one hour from Hangzhou and two hours from Shanghai by train.

2. Can I get free samples?

Yes, we provide free samples delivered within 2 days for evaluation.

3. How long does a quotation take?

Typically within 2 days, or we'll notify you promptly if confirmation is needed.

4. What's your production lead time?

5-15 working days after order confirmation, depending on quantity.

5. What about quality control?

Self-inspections at every stage, plus spot and final inspections by QC team using advanced equipment.

6. What's your largest advantage?

30+ years of expertise in converting yarn to finished products with quality guarantee.

7. What payment terms do you accept?

T/T, LC and more options available.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!