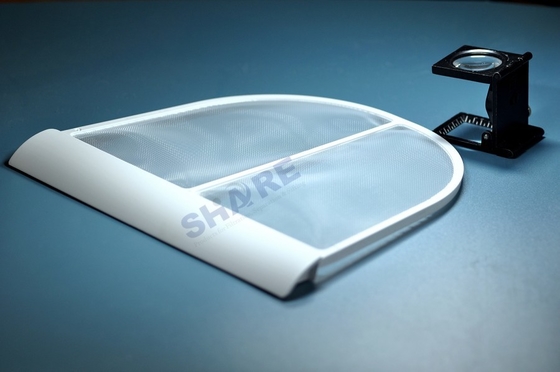

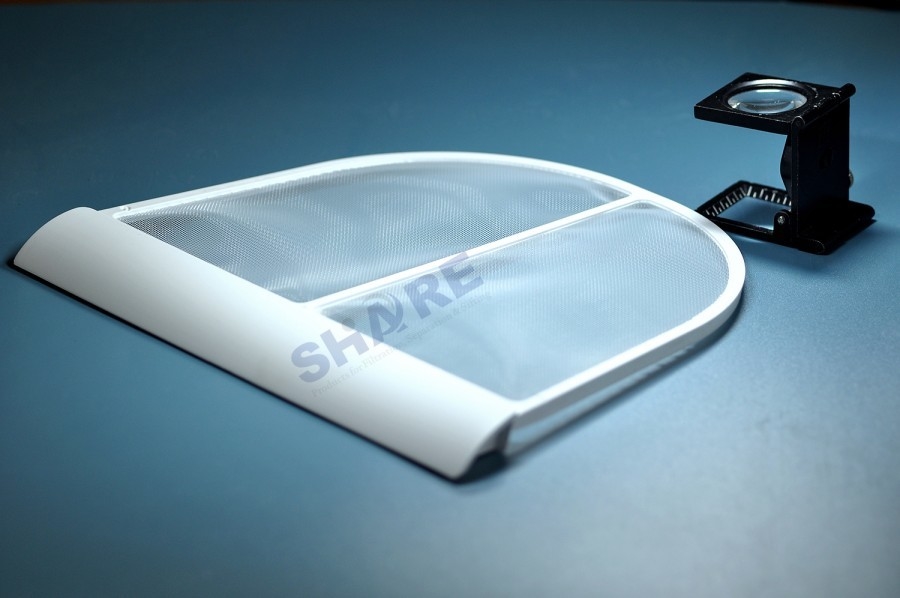

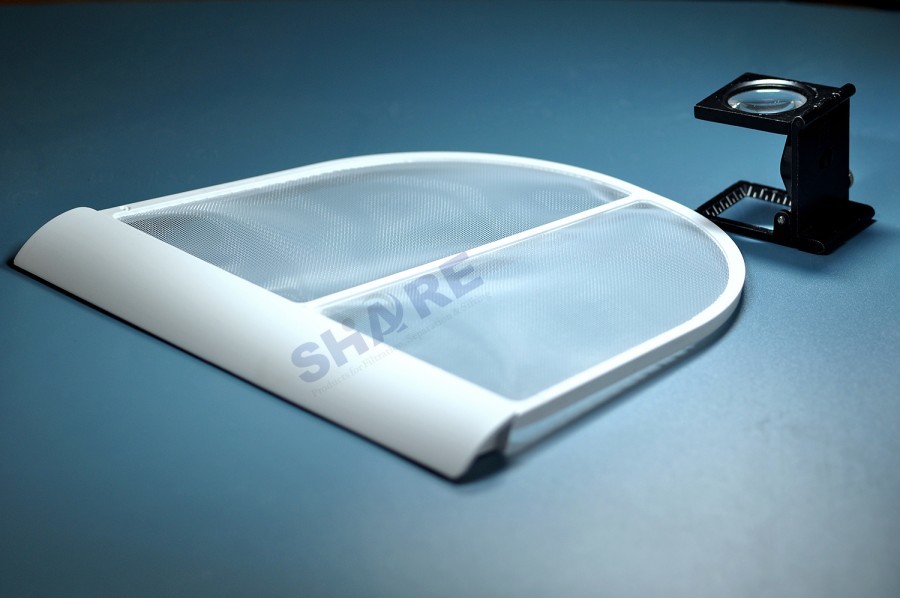

Polyester Filter Mesh Welded Continuous Tube Sleeve For Milling Equipment 23uM

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT

More information facilitates better communication.

Mr

- Mr

- Mrs

OK

Submitted successfully!

We will call you back soon!

OK

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT