Manufacturing in High Quality Materials, Precise Workmanship

In our factory we process filter mesh for screens and filters in all sizes and designs. Our business activities span from slitting, cutting or punching, welding, sewing, to mesh insert-moulding.

We manufacture according to customer’s design as well as to sketch or sample, considering the underlying standard tolerances and customized manufacturing standards. Experience and knowledge of our employees guarantee high-quality implementation.

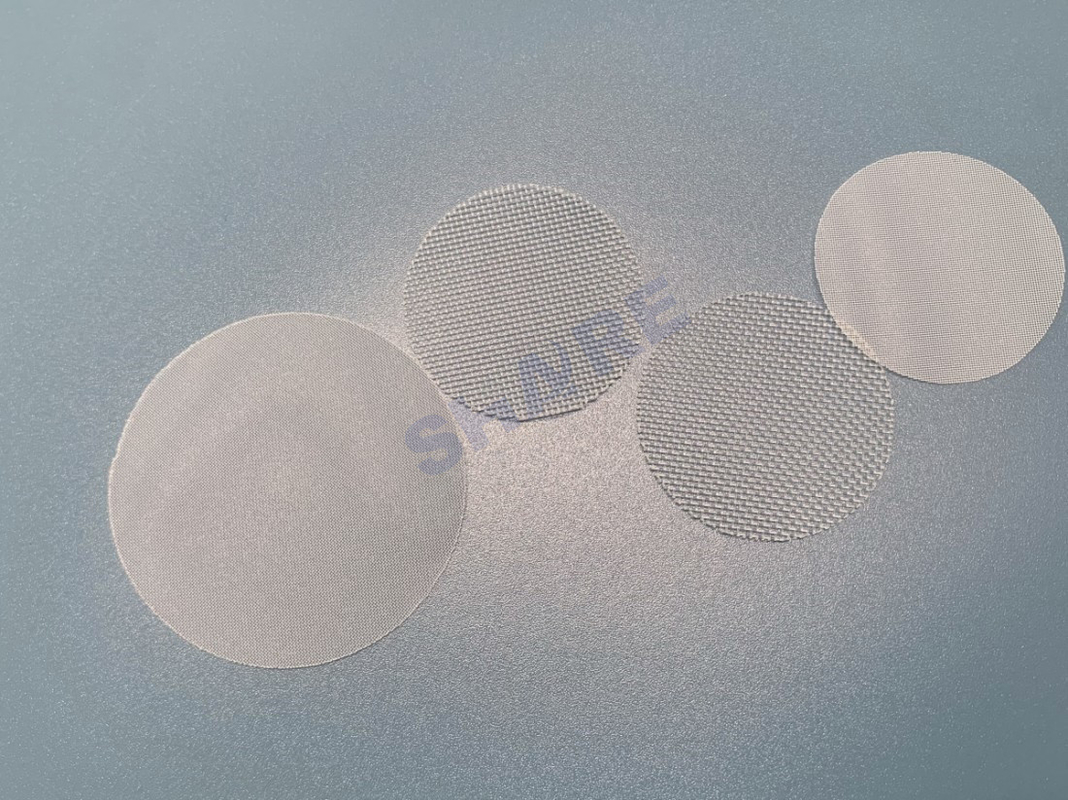

Plain Woven Filter Mesh

The width of filter mesh rolls can be in 100cm, 127cm, 150cm, 165cm, 175cm, 183cm, 365cm or other custom width. Length of roll can be 30m, 50m, 70m, or other custom length.

Filter Mesh Slitted in Narrow Ribbons

Our ribbons are used in a multitude of applications such as automotive filters, appliances filters, industrial filters, electronic devices, diagnostic test strips, perfusion and transfusion filters in healthcare. Share Filters ultrasonic slitting is also used for manufacturing fabric strips and produces a closed edge with very little material build up at the edge.

Laser Cutting Filter Mesh Shapes

Share Filters cutting method include Laser cutting, Cold cutting, Hot cutting, Slitting, Punching. Professional cutting using custom made tools that will not damage the meshes. Laser cutting allows for elaborate shapes to be cut that are specific to the customer’s design needs

Ultrasonic Cutting and Welding

Ultrasonic cutting and welding are accurate, clean. The tubes are equipped with one or two functional seams, which provide the necessary seam strength.

Custom Filter Bags

Rosin press bag

Biopsy bag

Sewn Mesh Bag

Standard Mesh Filter Bags

Share Filters produces and provides high quality liquid filter bags to fit standard size filter housing, as well as custom designed products where requested. The constituent materials have been chosen for their purity, with consistent high quality and repeatable performance.

Mesh Insert Plastic Injection Molded Filters

Our injection moulded filters products consist of a filter mesh held in a polymer plastic frame, allowing for a more robust part/product giving more reliability and longevity in its use.

About Us

Share Filters has over 20 years of experience developing and manufacturing filter mesh and custom product solutions for our customer's screen and filtration needs. We can offer the filter mesh and filter components services including slitting, cutting, welding, sewing and injection molding. Our customer base comes from a wide variety of industries– Automotive, Home appliances, Food and beverage, Milling, Medical, Life Science and laboratory, Electronical as well as more general engineering, giving us a wealth of experience in many areas.

Application of Share Filters Products

|

|

|

|

|

| Fuel filter |

Tranfusion filter |

Air purifier filter |

Coffee filter |

Drip irrigation filter |

| Automotive |

Healthcare |

Appliance |

Food & Beverage |

Agriculture |

Contact Us

Please connect with us so we can learn more about your application and design specifications!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!