What We Do

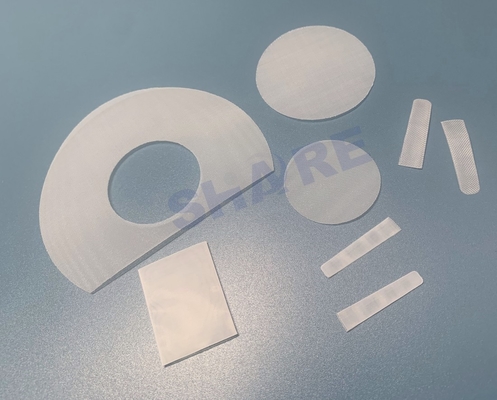

Share Filters specializes in helping our customers design and manufacture high quality mesh filter components to around the world. As a supplier combining the woven filter mesh manufacturing and filter mesh processing according to custom-made design, we are flexible enough to adapt to our customers’ production and delivery needs. Our advanced manufacturing processes and scientific machines allow us to create filtration products in any shape or configuration – from simple, traditional components like mesh shapes and filter bags to highly complex devices like custom plastic molded filters.

Share Filters’ customer base comes from a wide variety of industries including Automotive, Home appliances, Food and beverage, Milling, Medical, Chemicals, Agriculture, Life Science and Laboratory, as well as Electronical, giving us a wealth of filtration experience in many areas.

Application of Share Filters Products

Factory Capabilities

Share Filters sepcialize in manufacturing and offering filter mesh in different materials including nylon mesh, polyester mesh, pp mesh, metallic mesh, and we can also convert these filter meshes to filter mesh ribbons, filter mesh tubes, filter bags and mesh insert plastic molded filters to meet customs' Filtration demands.

Woven Filter Mesh

The width of filter mesh rolls can be in 100cm, 127cm, 150cm, 165cm, 175cm, 183cm, 365cm or other custom width. Length of roll can be 30m, 50m, 70m, or other custom length.

Filter Mesh Slitted in Narrow Ribbons

Share Filters heat slitting and ultrasonic slitting is also used for manufacturing fabric strips and produces a closed edge with very little material build up at the edge.

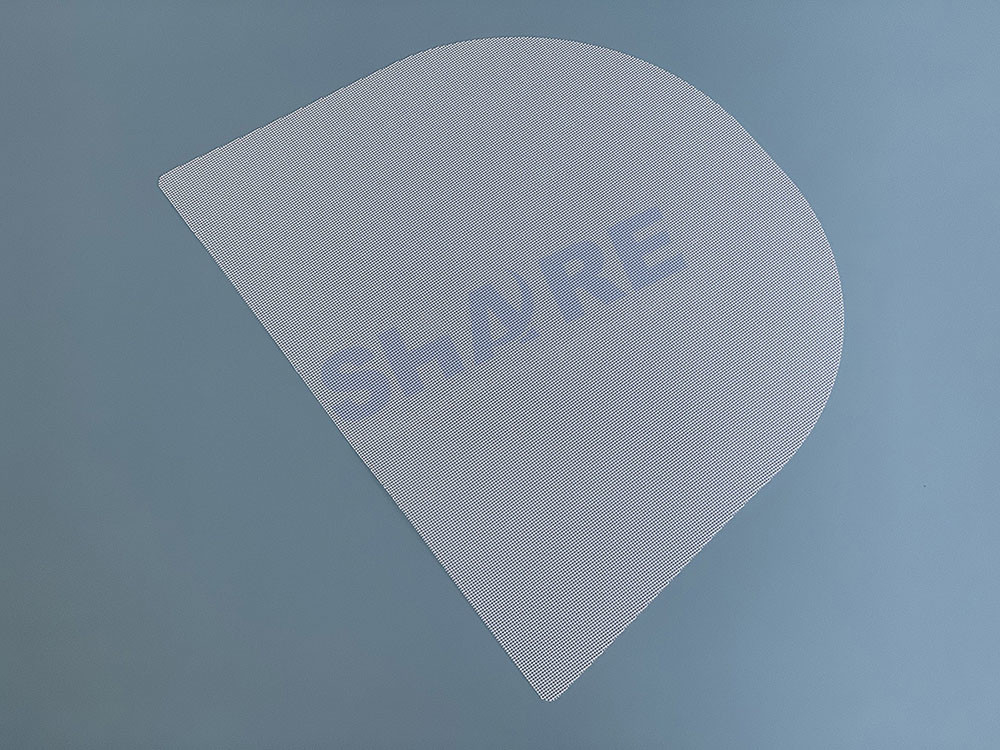

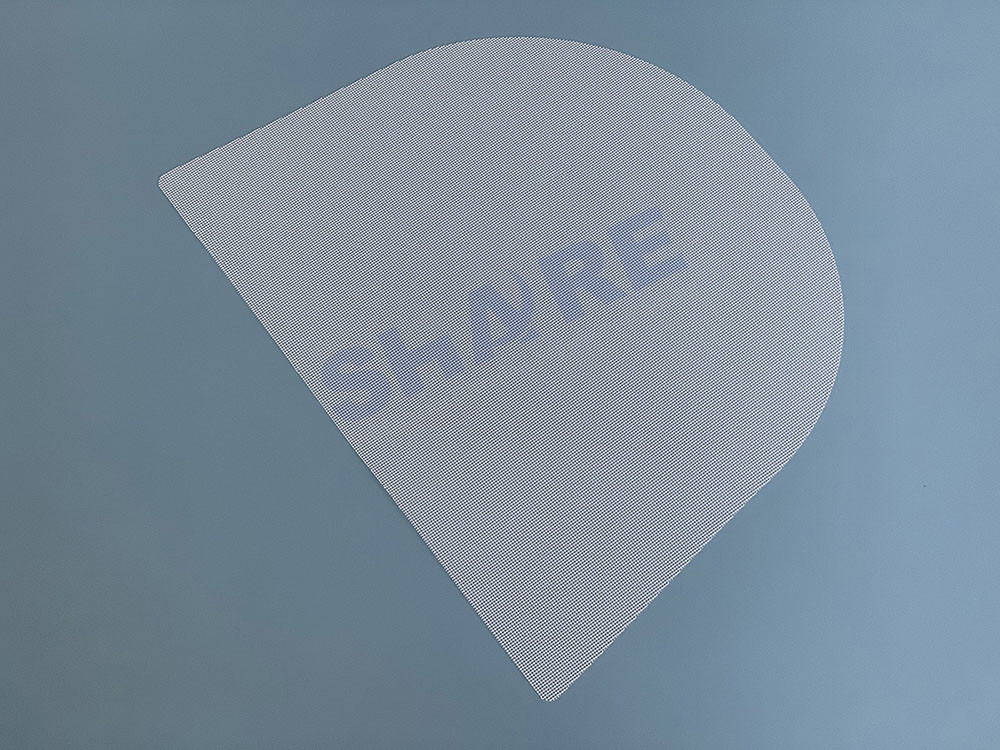

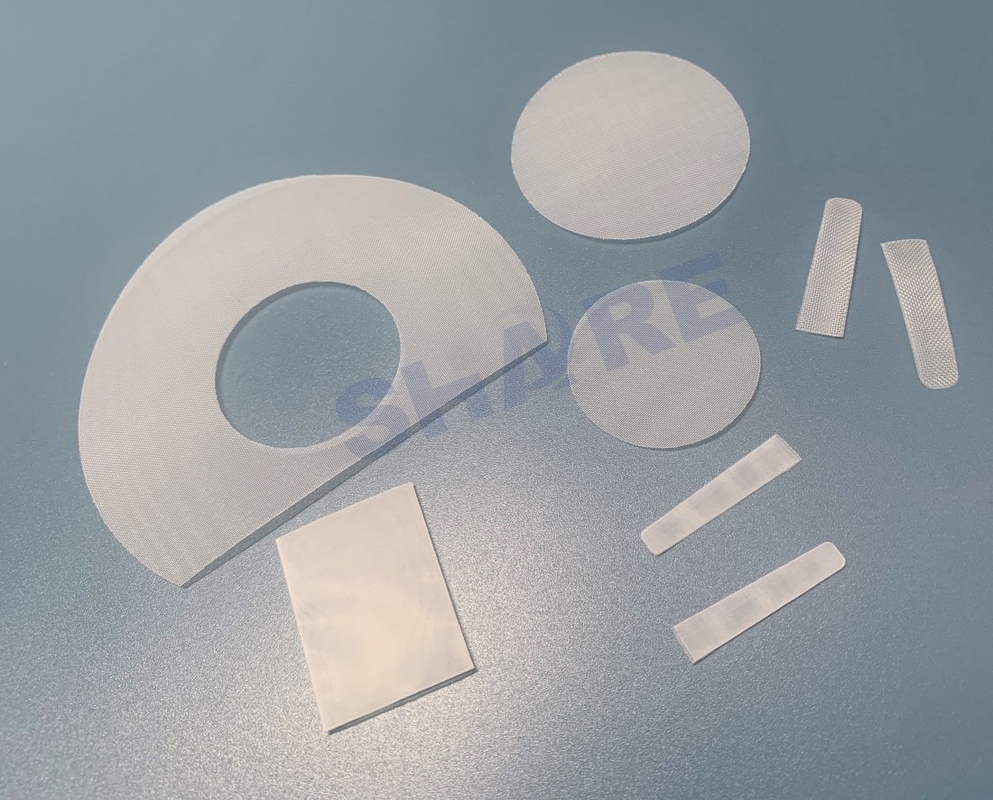

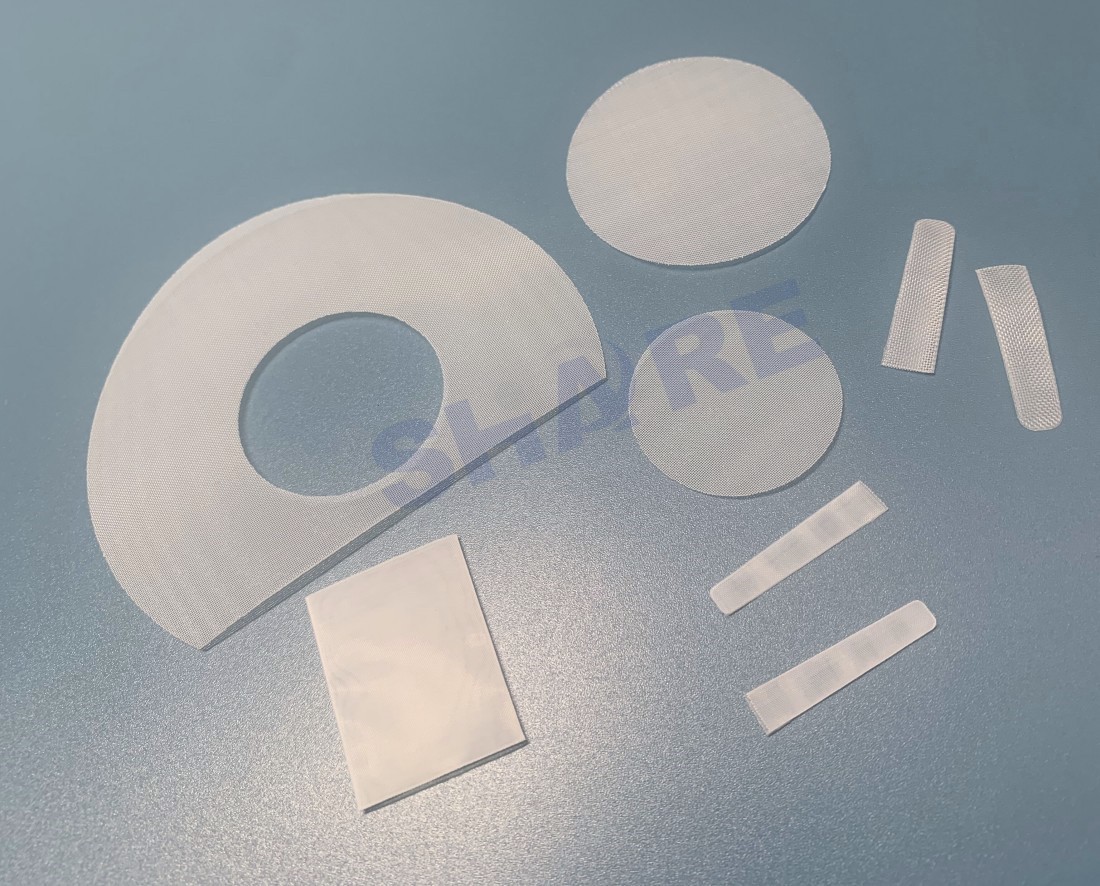

Laser Cutting Filter Mesh Shapes

Share Filters cutting method include Laser cutting, Cold cutting, Heat cutting, Slitting, Punching. Professional cutting using custom made tools that will not damage the fabrics. Laser cutting allows for elaborate shapes to be cut that are specific to the customer’s design needs

Ultrasonic Cutting and Welding

Ultrasonic cutting and welding are accurate, clean. The tubes are overlapped and equipped with one or two functional seams, which provide the necessary seam strength.

Custom Filter Bags

Rosin press bag

Biopsy bag

Sewn Bag

Standard Filter Bags

Share Filters produces and provides high quality liquid filter bags to fit standard size filter housing, as well as custom designed products where requested. The constituent materials have been chosen for their purity, with consistent high quality and repeatable performance.

Mesh Insert Plastic Injection Molded Filters

Our injection moulded filters products consist of a filter mesh held in a polymer plastic frame, allowing for a more robust part/product giving more reliability and longevity in its use.

Contact Us

Share Filters provides some information for filter mesh possible applications, but there are too many functions for comprehensive descriptions of possible uses. Therefore, when considering a potential application in your particular industry, please consider contacting us who will work with engineers and product designers in choosing the best products for their specific projects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!