Product Description

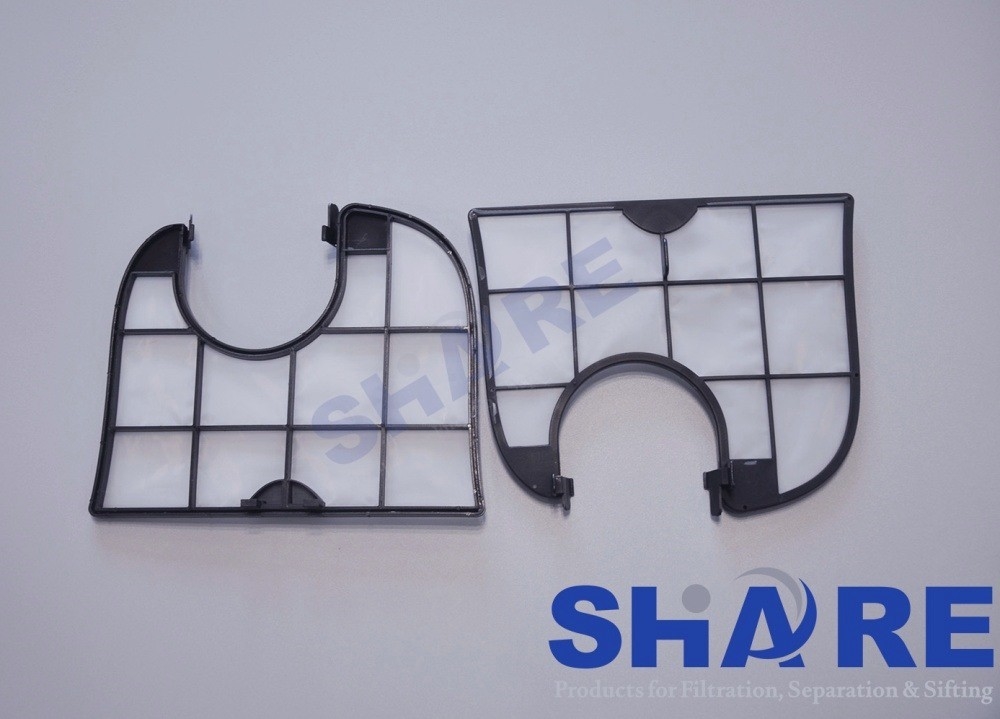

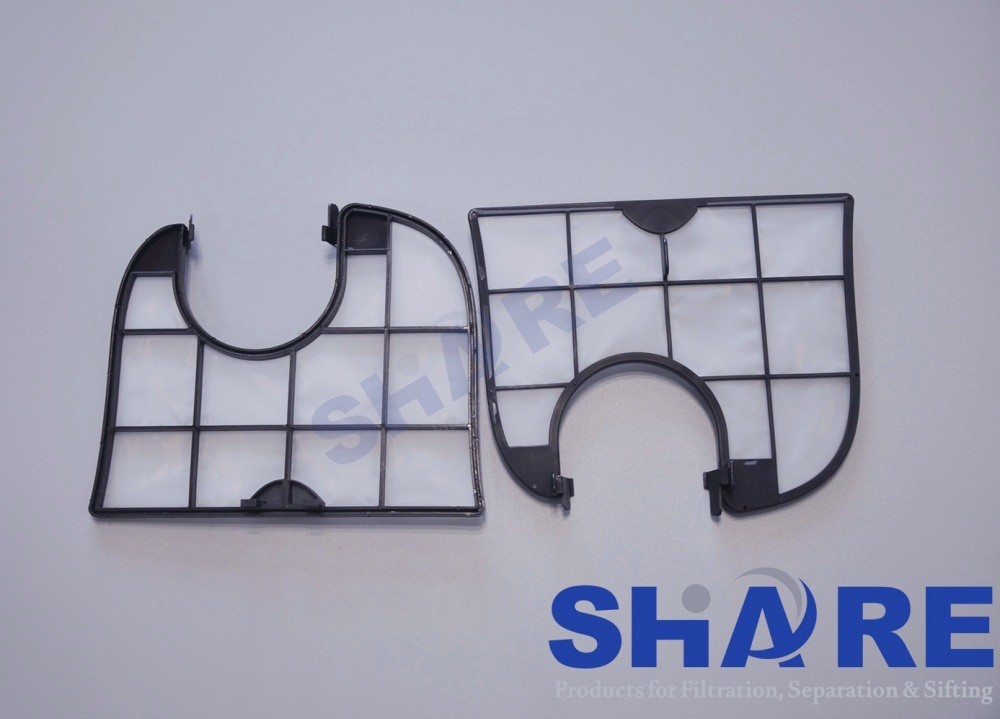

Air Filter Fit For Chainsaw OEM Mesh Insert Plastic Molded Filter

It is essential for chainsaws to having a clean and properly functioning air filter to keep optimal performance and longevity of the engine. The air filter prevents dust, debris, and other particles from entering the engine and causing damage.

Share Filters' OEM chainsaw air filter is made of synthetic filter mesh and thermoplastic by the processing of mesh insert injection molding. Thanks to wide range of filter mesh specifications that manufacture in-house, Share Filters' Chainsaw air filters can be available in different filtration ratings, which indicate the size of particles they can effectively capture. It's important to choose a filter with an appropriate rating that suits the requirements of Chainsaw.

Steps in the Making of a Custom-made Filter Element

Share Filters can take action at any stage of the custom filter element design process, either :

- In consulting: which is the right filter media for a sheet, bag, a strainer?

- In study: how to implement the filter mesh in a simple and economical way. Is it necessary to stitch, weld or inject?

- In production: prototyping, sample testing and then mass production.

Custom-tailored Plastic Molded Filters

Share Filtes Custom Plastic Molded Filter Materials Options

|

Support rim material |

PA6, PA66, PET, PP, ABS, POM, and other thermoplastics, metal |

| Filter media |

Nylon mesh, polyester mesh, PP mesh, stainless steel mesh, brass mesh |

| Micron rating |

16μm - 1500μm |

| Mesh parts fabrication |

Laser cutting, sonic cutting, punching, sonic welding |

| Process method |

Mesh insert injection moulding |

| Specification |

Custom |

| Colour |

Custom |

Properties of Polymer Plastic for Support Rim

PA6 (polyamide 6) Tough, abrasion-resistant, good vibration damping, resistant to solvents, fuels and lubricant

PA66 (polyamide6.6) Rigid, stiff, abrasion-resistant, dimensionally stable at heat exposure.

PET (polyethyleneterehthalate) High rigidity, high hardness, high chemical resistance, good dimensional stability.

PP (polypropylene) Good chemical resistance, more heat resistant than PVC

PEEK (polyetheretherketone) High mechanical strength, stiffness, toughness, temperature, chemical and radiation resistance

How To Select the Right Filter Mesh for Plastic Filter? You Can Follow These Points.

|

- Mesh size or the size of the particle you need to filter

- Mesh material (consider the working condition)

- Mesh thread diameter, Mesh thickness

- Opening area

|

Nylon Filter Mesh Data Sheet

| Ref. No. |

Mesh Count |

Thread Diam. |

Mesh Opening |

Opening Area |

| |

mesh/cm |

mesh/inch |

µm |

µm |

% |

| JPP5 |

5 |

12 |

500 |

1500 |

56 |

| JPP6 |

6 |

16 |

400 |

1267 |

58 |

| JPP7 |

7 |

18 |

350 |

1079 |

57 |

| JPP8 |

8 |

20 |

350 |

900 |

52 |

| JPP9 |

9 |

24 |

250 |

860 |

60 |

| JPP10 |

10 |

25 |

300 |

700 |

49 |

| JPP12 |

12 |

30 |

250 |

583 |

49 |

| JPP12 |

12 |

30 |

300 |

533 |

41 |

| JPP14 |

14 |

35 |

300 |

414 |

34 |

| JPP16 |

16 |

40 |

200 |

425 |

46 |

| JPP16 |

16 |

40 |

250 |

375 |

36 |

| JPP20 |

20 |

50 |

150 |

350 |

49 |

| JPP20 |

20 |

50 |

200 |

300 |

36 |

| JPP24 |

24 |

60 |

150 |

267 |

41 |

| JPP28 |

28 |

70 |

120 |

237 |

44 |

| JPP30 |

30 |

76 |

120 |

213 |

41 |

| JPP32 |

32 |

80 |

100 |

213 |

46 |

| JPP36 |

36 |

90 |

100 |

178 |

41 |

| JPP40 |

40 |

100 |

100 |

150 |

36 |

| JPP43 |

43 |

110 |

80 |

152 |

43 |

| JPP48 |

48 |

120 |

80 |

130 |

38 |

| JPP56 |

56 |

140 |

60 |

120 |

44 |

| JPP59 |

59 |

150 |

60 |

110 |

42 |

| JPP64 |

64 |

160 |

60 |

100 |

37 |

| JPP72 |

72 |

180 |

50 |

90 |

41 |

| JPP80 |

80 |

200 |

50 |

75 |

36 |

| JPP100 |

100 |

250 |

40 |

60 |

36 |

| JPP120 |

120 |

305 |

40 |

43 |

25 |

| JPP130 |

130 |

330 |

40 |

37 |

23 |

| JPP140 |

140 |

355 |

30 |

38 |

33.7 |

| JPP150 |

150 |

381 |

30 |

34 |

30.25 |

| JPP165 |

165 |

420 |

30 |

28 |

20.7 |

| JPP180 |

180 |

460 |

30 |

25 |

19.5 |

| JPP200 |

200 |

510 |

30 |

16 |

10.2 |

This data sheet just include our common specification, please contact us if you have other custom specification

What We Do

Share Filters specializes in helping our customers design and manufacture high quality mesh filter components to around the world. As a supplier combining the woven mesh manufacturing and mesh processing according to custom-made design, we are flexible enough to adapt to our customers’ production and delivery needs. Our advanced manufacturing processes and scientific plastic molding allow us to create filtration products in any shape or configuration – from simple, traditional components like mesh screens to highly complex devices like custom plastic filters.

Share Filters Workshops

Share Filters Products Applications

|

|

|

|

|

|

| Automotive |

Appliance |

Medical |

Food & Beverage |

Chemical |

Environmental |

FAQ about Plastic Molded Filters / Insert Molded Filters?

Can plastic molded filter specifications be customized?

Yes, most of our filters are customized, the filter’s materials, dimensions, shape, construction method, mesh size, and applications are all fully customizable.

Do you need drawings for production?

No, our engineer can consult with you to make a drawing based on a description or image of the filter you may have.

What are the common weaving types for plastic molded filters?

Plain weave mesh is the most common, but other options such as twill weave mesh are also used. The benefit of using plain weave mesh is that it is the most popular, affordable and easy to clean.

What factors should be anticipated in which plastic or resin should be selected?

When selecting the right plastic for your application, you need to clearly outline the physical requirements of the part, including potential stressors, environmental conditions, chemical exposure, and expected service life of the product.

Contact us

Please connect with us so we can learn more about your application and design specifications!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!