Product Description

Monofilament PPS Material Membrane Support Mesh

Characteristics

- Ultra-high porosity, minimizing impact on membrane functionality.

- Mesh (fabric) has uniform structure, ensuring consistent size control.

- Various of product options available.

Applications

Can be used in hydrogen production, fuel cells, electrolysis membranes, and other areas as membrane or electrode support materials.

Mesh Specifications

| SHARE PPS Filter Mesh Technical Datasheet |

| Material |

Item No. |

Specification |

Thread Diameter |

Mesh Opening |

Open Area |

Mesh Thickness |

Weight |

Tensile Breaking Strength |

Tensile Elongation |

| |

|

|

μm |

μm |

% |

μm |

g/m2 |

(N/5CM) (warp/weft) |

(%) (warp/weft) |

| PPS |

20T-140 |

350/51PW |

140 |

350 |

51 |

260 |

86 |

660/643 |

29.5/27.8 |

| PPS |

20T-150 |

340/48PW |

150 |

340 |

48 |

280 |

100 |

766/755 |

29.5/28.4 |

| PPS |

47T-55 |

156/55PW |

55 |

156 |

55 |

100 |

34 |

246/253 |

26.4/30 |

PPS

(Toray yarn) |

20T-150 |

340/48PW |

150 |

340 |

48 |

287 |

100 |

810/780 |

24/24 |

PPS

(Toray yarn) |

59T-45 |

125/54PW |

45 |

125 |

54 |

80 |

27 |

210/210 |

17.7/17.7

|

Note: The above are just three commonly used specifications and not the complete list. Please contact us for more specifications and information.

PPS Mesh for Alkaline Water Electrolysis (AWE)

In the process of alkaline water electrolysis for hydrogen production, PPS mesh (polyphenylene sulfide mesh) typically acts as a support structure within the electrolyzer due to its excellent mechanical properties, robust alkali resistance, and outstanding electrochemical traits. Its roles are as follows:

Support Structure: SHARE PPS mesh provides physical support, helping to maintain separation and orderly arrangement within the electrolyzer, ensuring the effective distribution of electrical current.

Enhanced Conductivity: Due to its excellent chemical stability and conductivity, PPS mesh can help improve electrolysis efficiency.

Corrosion Resistance: PPS material is highly resistant to alkaline environments, maintaining structure and functionality without corrosion during the electrolysis process.

Improved Hydrogen Purity: As a separation layer, PPS mesh helps to segregate the produced hydrogen and oxygen, enhancing the purity of the hydrogen output.

Increased Surface Area: The structure of our PPS mesh provides a large surface area, which helps increase the area for electrolytic reactions and, consequently, the production of hydrogen.

Strength and Stability: Our PPS mesh maintains stability owing to its high strength and thermal stability, even under high temperatures and prolonged electrolysis, contributing to the long-term stability of alkaline water electrolysis systems.

Features

Affordable pricing

Uniform fabric structure

High porosity and large surface area

Exceptional corrosion resistance, thermal stability, and flame retardancy

Applications

From what we've gathered, our clients are mainly using our PPS mesh for

- ion exchange processes

- alkaline water electrolysis for hydrogen production

- feed and food drying

- filter for food, semiconductor and chemical applications

- chemical catalyst substrates

- oil-water separation

- gas filtration and purification

- wastewater treatment

- air pollution control

- desalination

- and more…

Product Options

PPS mesh specifications are designed to cater to a diverse array of applications. The available mesh options are in the following range:

Thread Diameter

30 - 250 µm

Mesh Count

25 - 420 per inch

Mesh Opening

30 - 800 µm

Open Area

25 - 60%

Mesh Thickness

56 - 508 µm

Pattern

Plain weave, twill weave

Width

Up to 300cm (Can be cut to specific widths such as 100 cm or 200 cm, or customized to any width as per request)

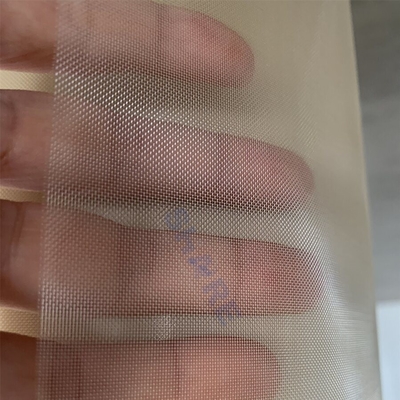

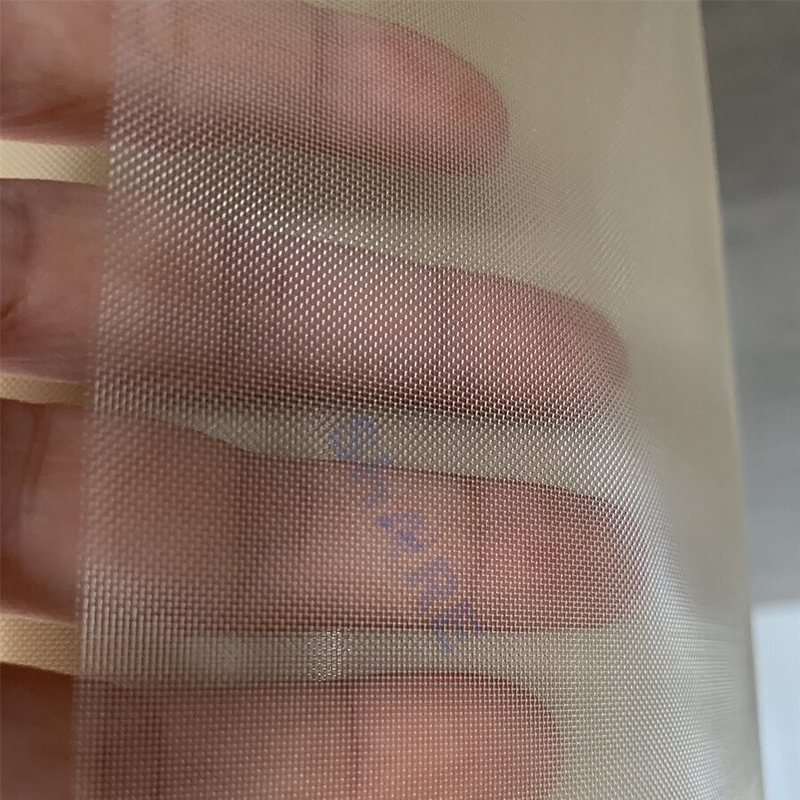

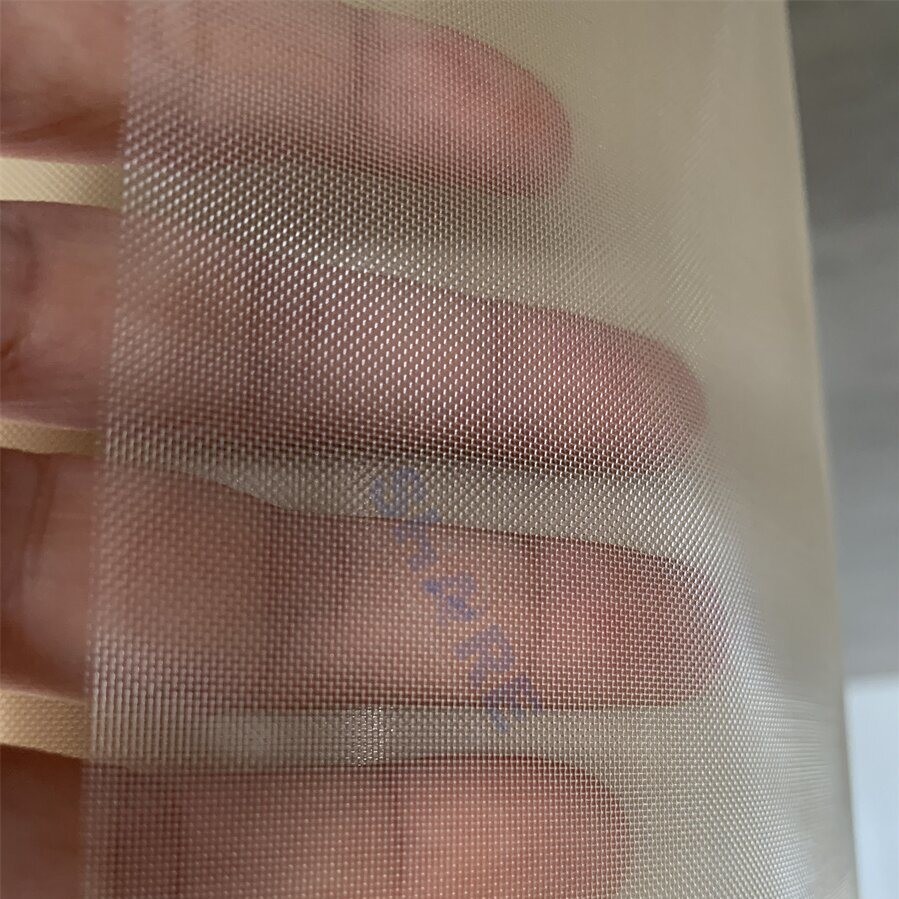

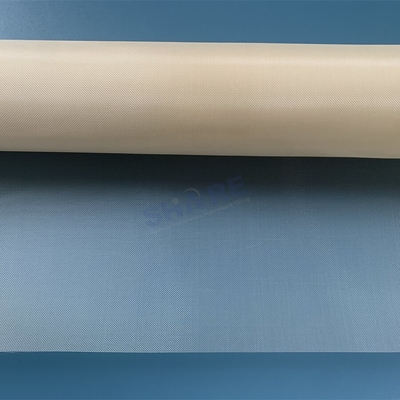

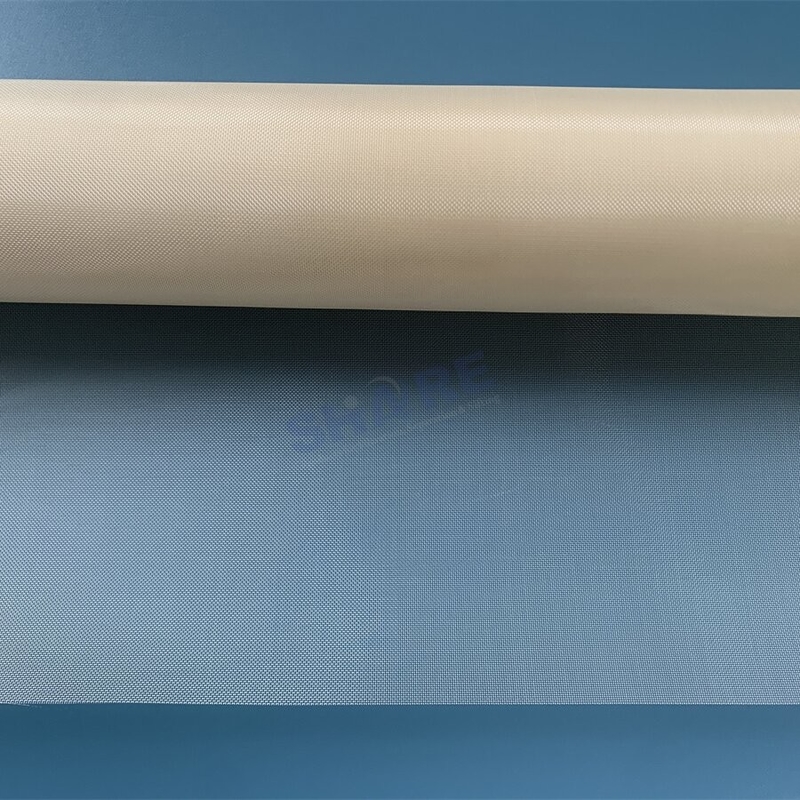

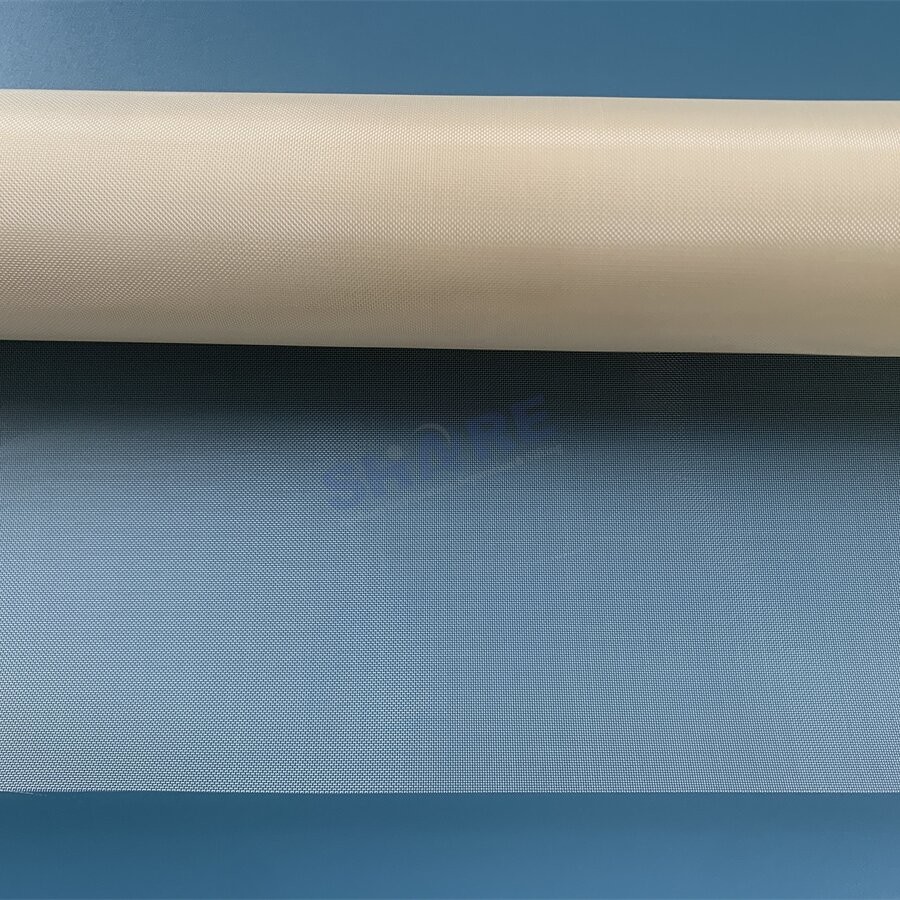

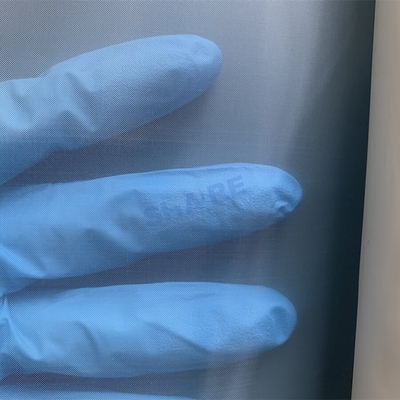

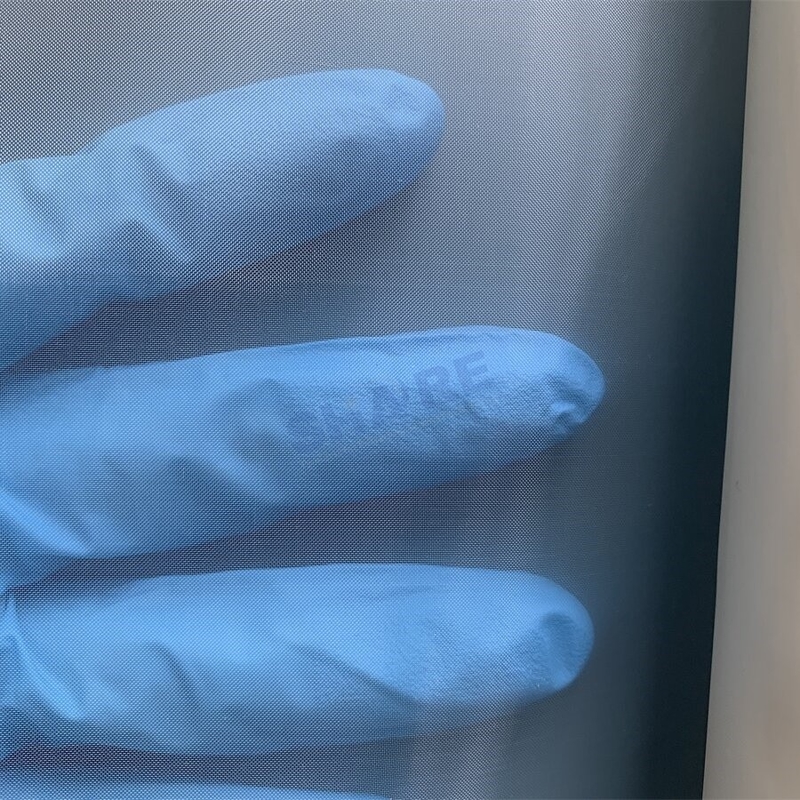

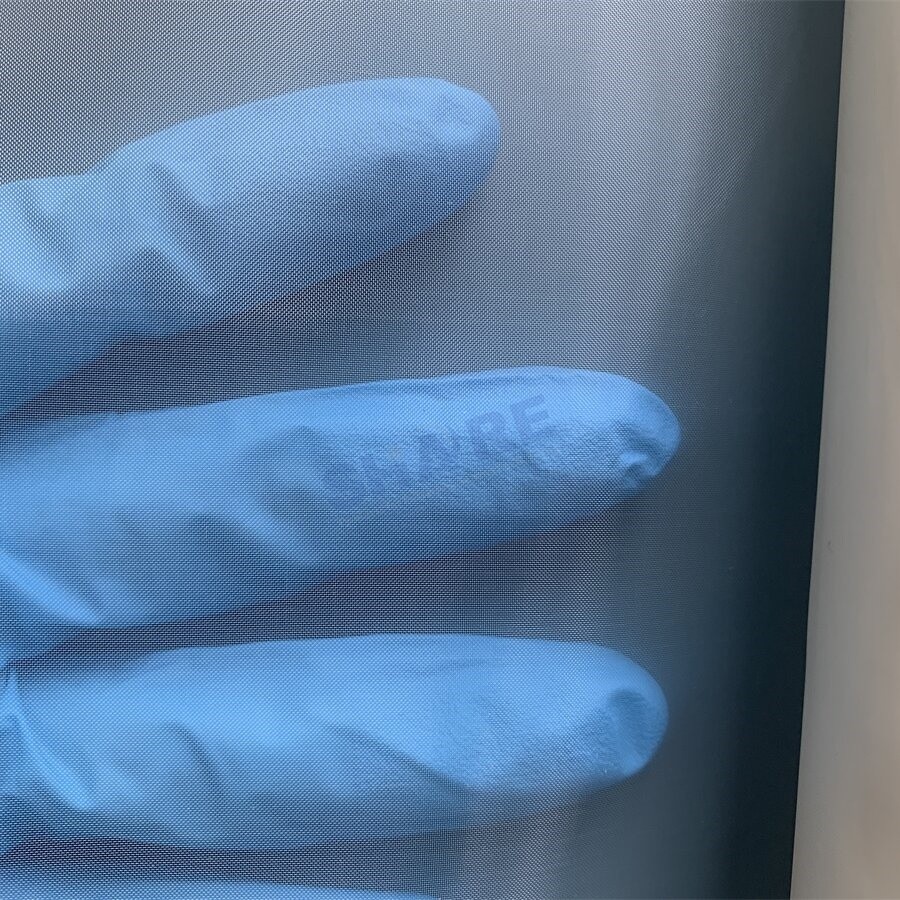

Real Images

Packaging & Shipping

1. Rolled on the paper core or plastic pipe, packed into PE bags

2. Put into standard export carton

3. Put into PP woven bag to prevent damage during transportation

The label contains the following standard information:

item name, manufacturer, material, dimensions, manufacturing date, order number, batch number etc.

| |

Port to Port |

Door to Door |

| Express(DHL,UPS,FEDEX, EMS) |

|

1 - 5 days |

| Air Freight |

1 - 5 days |

4 - 10 days |

| Sea Freight(FCL) |

15 - 30 days |

20 - 35 days |

| Sea Freight(LCL) |

15 - 30 days |

22 - 37 days |

FAQ

1. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are one hour away from Hangzhou and two hours away from Shanghai.

2. Can I get free samples and how long can you deliver them?

We are pleased to provide you with free samples for your evaluation, which will be sent to you within 2 days. Please feel free to reach out to us for samples.

3. How long does a quotation take?

In most cases, we respond within 2 days. If something in RFQ need be confirmed, we will promptly notify you soon.

4. How quickly can I get my order finished?

The production lead time is dependent on the quantity. Typically, it takes 5 to 15 working days for us to complete mass production once you have placed the order.

5. What about your quality control?

By visual inspection, optical or pressure sensitive equipment and automated 3D image-inspection equipment, our production operators conduct self-inspections at every stage of the process. Additionally, we have spot inspections and final inspections carried out by our Quality Control (QC) team.

6. What's your largest advantage?

One of our core competencies is our excellent converting capabilities from yarn over weaving to converted items with professional technical team and quality guarantee and management for more than 30 years.

7. What kind of payment terms do you accept?

T/T and LC and more.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!