Photos of Factory

|

| Warping |

Weaving |

Inspection |

|

| Washing |

Heat setting |

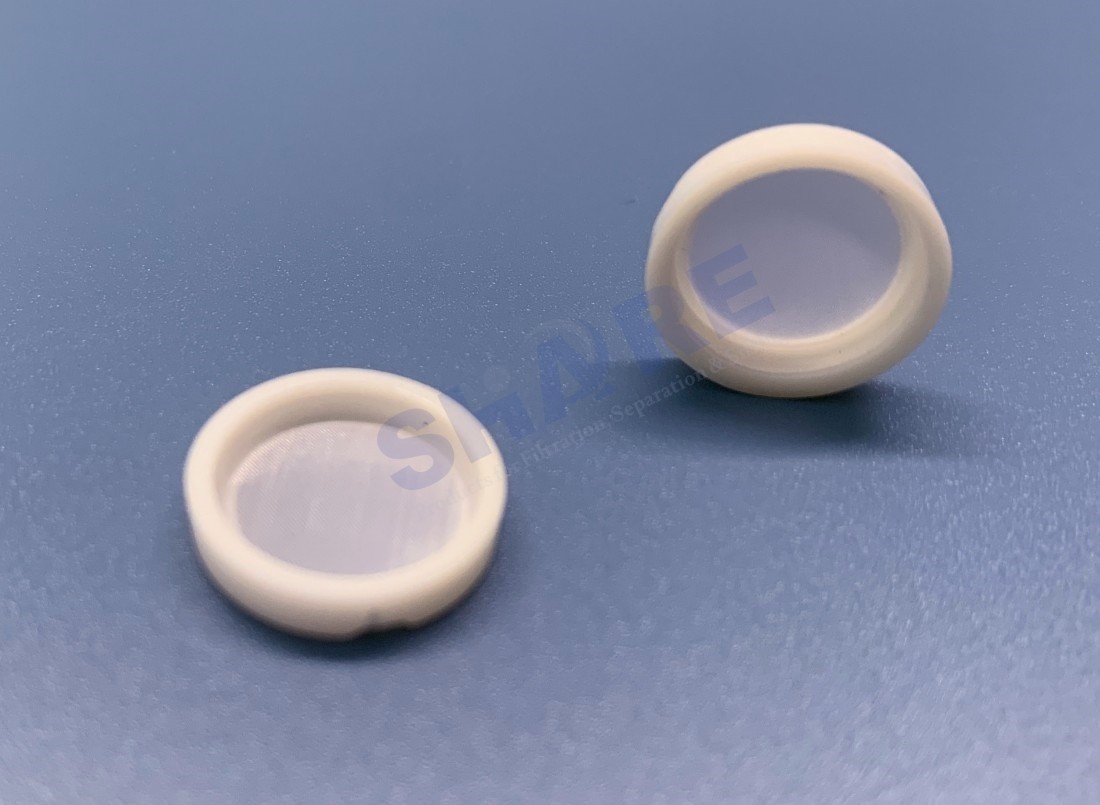

Injection moulding |

FAQ

Are You Factory or Trade Company ?

We're factory, and manufacture our products in-house.

Where Is Your factory Located? How Can I Get There?

We are in Tiantai city, Zhejiang province China. By train, one hour away from Hangzhou and two hours away from Shanghai.

Can I Get Free Samples ?

We are pleased to provide you with free samples for testing, just the freight will be at your account.

When Can I Get the Quotation ?

Normally we can offer the quotation within 48 hours.

What's Your Payment Term ?

T/T and LC and more.

What's the Lead Time of the Order?

The production lead time is dependent on the quantity. It takes 5 to 20 working days for us to complete mass production after receive the payment.

What About Your Quality Control?

By visual inspection, optical or pressure sensitive equipment and automated 3D image-inspection equipment, our production operators conduct self-inspections at every stage of the process, from the raw material to finshed products. Additionally, we have spot inspections and final inspections carried out by our QC team.

Why Choose You ?

One of our core competencies is our excellent processing capabilities, convert the woven filter mesh to mesh ribbons, discs, shapes, tubes, bags, plastic moulded filters, with advanced equipments and professional technical team for more than 20 years. We're the few supplier who have experience with synthetic filter meshes and are able to use them with plastic moulding in good conditions.

How To Delivery the Order?

Small batch is sent by UPS, Fedex, TNT, DHL, EMS, ect, high volume will be shipped by sea and air.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!